Evaluating

Automated Power Distribution Systems

Using

Computer Simulations

Hesham

E. Shaalan, Ph.D.

Engineering

Technology Program

Texas

A&M University-Corpus Christi

Email:

hshaalan@falcon.tamucc.edu

ABSTRACT

Electric utilities are frequently

faced with the need to spend millions of dollars on distribution system expansion.

Distribution automation provides a tool to achieve maximum utilization of the

utility's physical plant, and to provide high quality of service to its customers.

The challenge is to identify and evaluate potential automation functions and

determine those appropriate for implementation. It is also important to examine

potential costs and benefits of distribution automation. A computer-aided approach

simulates distribution automation functions before actually implementing them,

saving substantial amounts of time and money. A software package developed for

the Electric Power Research Institute is used to perform the simulations. This

paper presents the cost-benefit analysis of a distribution automation plan based

on modeling a section of a Georgia Power Company service area. The analysis

will provide potential economic benefits along with improved efficiency due

to the implementation of distribution automation.

INTRODUCTION

Power distribution represents

the final link between the total electric power supply system and the customer.

Thus, over the next decade, millions of dollars will be spent in

distribution system expansion. Automating the power distribution system can make

the overall system operate more efficiently. Increased efficiency on the

distribution level improves the use of existing facilities on the distribution,

transmission, and generation levels. Thus, distribution automation provides a

tool to achieve maximum utilization of an electric utility's physical plant and

to provide the highest quality of service to its customers. Clearly, both the

utility and its customers can benefit from successful distribution automation

projects1.

The technology required to

implement distribution automation is available today.

Many devices are now available that can automate system functions such as

automatic switching. The challenge is to identify and evaluate potential

automation functions and determine those appropriate for implementation. It is

therefore important to examine potential costs and benefits of distribution

automation1. Moreover, the economic aspects are becoming more

important due to the recent

deregulation

of the power industry, which introduced more competition. Therefore,

distribution automation provides a competitive edge to the utilities that

implement it.

The application of distribution

automation can increase asset utilization, lower operating costs, and reduce

outage times. However, all projects must be evaluated based on tangible savings

and costs, which are not easy to quantify. In some cases, utilities have not

been able to perform studies that can provide accurate and dependable results.

A computer-aided approach can

be used to simulate distribution automation functions before actually implementing

them, saving a substantial amount of time and money. A software package developed

for the Electric Power Research Institute (EPRI) can be used to perform such

simulations2. There are other commercially available software packages

that can also perform similar analyses such as the software from PowerWorld

(www.powerworld.com),

EDSA (www.edsa.com),

and ASPEN (www.aspeninc.com). This paper presents the cost-benefit analysis of a distribution

automation plan based on modeling a section of a Georgia Power Company service

area. The analysis will examine potential costs and benefits of specific automation

functions. The economic benefits to Georgia Power Company will be calculated

along with improved performance measures such as system efficiency.

DEWORKSTATION DESCRIPTION

The Electric Power Research

Institute Distribution Engineering Workstation (DEWorkstation) provides a

computer aided engineering workstation environment to perform design and

operational studies for distribution systems. DEWorkstation is conceptually

divided into four major parts: a relational database, Graphical User Interface

(GUI), an Application Programmer Interface (API), and applications used for

analysis, design and operational studies. DEWorkstation has also been designed

to provide users with a platform suitable for distribution automation

evaluations.

The

GUI interface incorporates data from the database into distribution system

models. Substations and circuits can be entirely built and edited with mouse

and/or keystroke operations. Once a distribution system model has been created

with the GUI, any application module may be used for engineering studies.

DEWorkstation

is designed to meet the analysis, planning, design and operation needs of

distribution engineering through its available application modules. These

modules perform, among others, the following types of analyses: power flow, line

impedance calculation, economic analysis, distribution transformer sizing, and

cable pulling analysis.

The

open architecture framework of DEWorkstation supports future expansion. This

architecture allows for applications to request data or results from other

applications and for users to easily add, delete, or replace applications3.

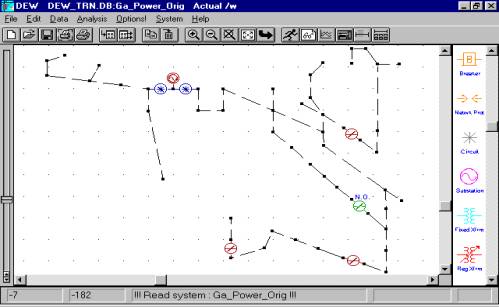

Figure 1 shows the main screen of the workstation’s graphical user interface.

The system shown in the figure represents the section of a Georgia Power Company

service area that is being modeled. The dashed lines represent line segments of

various lengths. The symbol at the source represents a distribution substation

with two circuits starting at that point. The other symbols represent manual

switches or sectionalizing devices.

DEWorkstation

was previously used in an undergraduate course on power distribution systems

at Georgia Southern University. Several assignments were utilized to give students

a chance to perform distribution system analysis and design studies4.

Realistic examples such as the one presented here were used to illustrate to

students the practical application of DEWorkstation5.

DISTRIBUTION AUTOMATION

Electric

utilities are constantly seeking ways to reduce costs and improve system

performance. Recently, the availability of distribution automation equipment has

given utilities more choices in the design of distribution systems. Therefore,

distribution automation is now an important consideration in upgrading existing

systems and designing new ones. Economic evaluation of distribution automation

is also important since it facilitates the examination of associated costs and

benefits.

Automation can be thought of as doing

a repetitive task with minimal human intervention6. Distribution

automation refers to automation of repetitive tasks on the distribution system.

Automated switching techniques can be used to enhance the capabilities of a

power distribution system. An automatic switch can be defined as a switching

device that opens and closes to connect two or more sections of a power distribution

system, with the aid of computer control by remote communications. However,

manual switches are commonly used in present power distribution systems.

|

Figure 1. DEWorkstation Screen Showing Existing System

The

idea behind automatic switching is that when load peaks change in different

areas of the system, the switch opens or closes to direct power to the location

where it is needed. This is an important factor due to the time varying nature

of different load types, or load diversity. Automatic switching can also be

performed as frequently as needed in contrast with manual switching.

Furthermore, an automatic switch can quickly isolate faulted sections of the

network to minimize power interruption. The time required for these switching

operations is reduced to a few minutes due to computer control and remote

communications. By contrast, manual switches require a minimum of one to two

man-hours. By replacing manual switches with the automated type, power flow can

be altered much faster and cheaper.

ECONOMIC

ANALYSIS

Electric

utilities are frequently faced with the need to make informed decisions

regarding alternatives involving money. These alternatives may involve the

implementation of a distribution automation function or the replacement of old

equipment. The problem is made more complex because expenditures associated with

a given project may occur at different times in the life of the project. An

economic equivalence function, such as present worth, provides a common economic

evaluation measure.

Money

has a time value since both inflation and interest rates determine the value of

an amount at given points in time. In a present worth analysis, monetary amounts

occurring at different times in the future are reflected to the present time. By

doing so, competing alternatives may be placed on equal footing, and the

appropriate economic choices can be made. The present worth of total annual

costs will be determined for the modeled section of the Georgia Power network

based on a 5% interest rate.

The

two main factors being considered here when comparing alternatives are

efficiency and total annual cost. Efficiency is evaluated in the form of kWh

line losses. One way to reduce distribution system losses is to change the way

the system serves the load by reconfiguring the switches. Switching will

distribute loads in a better way that will reduce the distribution system line

losses7. Reference 7 provides more information on the algorithm used

by DEWorkstation.

The

costs associated with an alternative can be expressed as capital cost and

operating expense. The capital cost is associated with the initial placement of

equipment including purchase price and installation cost. The operating expense

is associated with the ongoing operation of equipment. The yearly cost

associated with capital cost is referred to as a carrying charge8.

The carrying charge factor is used to reduce capital costs to a yearly amount,

and it is assumed here to be 20%. Thus, the total annual cost is the sum of

carrying charges and operating expenses.

The

operating expenses consist of maintenance cost and the cost of losses. The

maintenance cost is based on the scheduled maintenance of all equipment as well

as the labor cost. The cost of losses is based on the total system kWh losses

multiplied by the generation cost of $0.05/kWh.

EVALUATION RESULTS

The

modeled section of the Georgia Power network represents an existing system that

contains only manual switches for power flow control as shown in Figure 1. The

switch designated by “N.O.” indicates its normally open status, while the

other three switches are normally closed. Several types of loads exist on the

network such as residential, commercial, and industrial loads. An annual load

growth factor of 1% is used based on the historical data and future predictions.

Additional information is not provided in this paper due to the confidentiality

of the data.

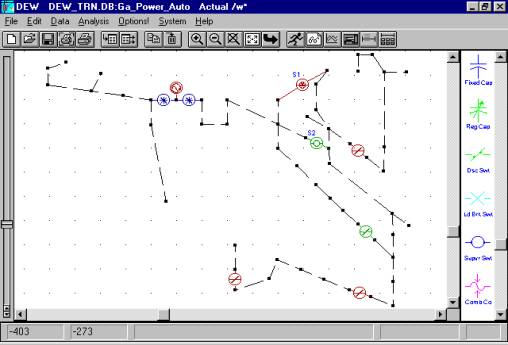

The

automated system is assumed to have two automatic switches installed in addition

to the existing four manual switches as shown in Figure 2. The two automatic

switches are designated by “S1” and “S2” in Figure 2. The capital cost

of the two automatic switches is estimated to be $32,000. The capital cost

includes all necessary equipment such as remote terminal units and communication

equipment8.

The

advantage of using automated switching is that switches open or close, directing

power to where it is needed in response to peak load changes throughout the

system. In addition, automatic switches can be operated as frequently as needed

in contrast with manual switches. Consequently, reconfiguring the system to

deliver power more efficiently can reduce line losses.

The

two alternative systems are designated here as the “Original” and the

“Automated” system. The following results were obtained for both systems

based on the analysis performed by DEWorkstation software.

All existing equipment in the original system is assumed to be paid for since it has been installed for more than ten years. In other words, there are no carrying charges associated with the original system. The automated system has carrying charges associated with the capital cost of the automatic switches. The carrying charge factor is assumed to be 20%, which means the capital cost is approximately divided over five years. Therefore, the analysis period for both systems is five years.

|

Figure

2. DEWorkstation Screen Showing Automated System

Table

1 shows the total annual kWh losses for both systems over five years. It should

be noted that these losses represent the analysis time periods of 24 hours a

day for 365 days. Comparing the results of the two systems indicates that the

automated system can provide a 7.8% reduction in losses every year. Figure 3

shows plots of annual losses for both systems, which illustrate the difference

between them. The cost of these loses over five years is shown in Table 2 for

both systems.

The

total cost for the original system as well as the automated system is shown

in Table 3. The components of the total cost for the original system are cost

of losses and maintenance cost. The automated system has the additional component

of carrying charges. Comparing these results indicates that the automated system

can reduce total costs by 5.4% in the first year, with similar reductions in

subsequent years. Figure 4 shows plots of total annual costs for both systems,

illustrating the difference between them. The present value of total annual

costs over five years is $1,342,690 for the original system and $1,271,721 for

the automated system, which represents a saving of $70,969.

Year |

Original System |

Automated

System |

Automated

System Reduction |

|

1 |

5,856,097 |

5,400,820 |

455,277 |

|

2 |

5,973,549 |

5,509,120 |

464,429 |

|

3 |

6,093,361 |

5,619,598 |

473,763 |

|

4 |

6,215,582 |

5,732,296 |

483,286 |

|

5 |

6,340,259 |

5,847,259 |

493,000 |

Year |

Original

System ($) |

Automated

System ($) |

Automated

System Savings ($) |

|

1 |

292,805 |

270,041 |

22,764 |

|

2 |

298,677 |

275,456 |

23,221 |

|

3 |

304,668 |

280,980 |

23,688 |

|

4 |

310,779 |

286,615 |

24,164 |

|

5 |

317,013 |

292,363 |

24,650 |

Table 3. Total Cost for Original and Automated Systems

Year |

Original

System ($) |

Automated

System ($) |

Automated

System Savings ($) |

|

1 |

298,405 |

282,249 |

16,156 |

|

2 |

304,445 |

288,158 |

16,287 |

|

3 |

310,609 |

294,197 |

16,412 |

|

4 |

316,898 |

300,370 |

16,528 |

|

5 |

323,315 |

306,679 |

16,636 |

|

|

Figure 3. Total annual losses for original and automated systems

CONCLUSION

Distribution automation is becoming an important consideration in upgrading existing systems and designing new ones. Economic evaluation of distribution automation is essential since it provides a good measure of potential costs and benefits. The results obtained in this paper are based on a modeled section of the Georgia Power Company network, which represents an existing system. The results were based on modeling the system using DEWorkstation software.

The results show that using automated switching improved system efficiency by lowering line losses. Furthermore, the total costs associated with the automated system were lower than the original system. This is because the additional carrying charges associated with automatic switches were still lower than the additional cost of losses associated with the original system. Accordingly, distribution automation can provide economic benefits as well as improved system performance.

ACKNOWLEDGEMENT

The author gratefully acknowledges the help of Georgia Power Company for providing the data.

REFERENCES

1.

R. Broadwater, H. Shaalan, W. Fabrycky, and R. Lee, “Decision Evaluation

With Interval Mathematics: A Power Distribution System Case Study,” IEEE Transactions

on Power Delivery, Volume 9, Number 1, January, 1994, pp. 59-67.

2.

H. Shaalan, J. Thompson, R. Broadwater, M. Ellis, and H. Ng, “Distribution

Engineering Tool Features a Flexible Framework,” IEEE Computer Applications

in Power, Volume 8, Number 3, July 1995, pp. 21-24.

3. H. Shaalan, J. Thompson, R. Broadwater, H. Ng, “DEWorkstation: A Comprehensive Distribution Modeling Tool,” Proceedings of the 1996 IEEE/PES Transmission and Distribution Conference, Los Angeles, CA, September 15-20, 1996, pp. 7-12.

4.

H. Shaalan, “Using Engineering Software to Teach Electric Power Distribution,”

The Technology Interface, Volume 3, Number 2, Spring 1999.

5.

H. Shaalan, "Using Simulations of Actual Power Distribution Systems

as an Educational Tool," Proceedings of the 2002 North American Power Symposium,

Tempe, AZ, October 14-15, 2002, pp.

516-518.

6.

Distribution Automation: IEEE Tutorial Course Number 88EH0280-8-PWR,

Piscataway, NJ, 1988.

7.

R. Broadwater, A. Khan, H. Shaalan, and R. Lee, “Time Varying Load Analysis

To Reduce Distribution Losses Through Reconfiguration,” IEEE Transactions on

Power Delivery, Volume 8, Number 1, January, 1993, pp. 294-300.

8.

H. Shaalan and R. Broadwater,

“Using Interval Mathematics in Cost-Benefit Analysis of

Distribution Automation,” Electric Power Systems Research Journal, Volume

27, Number 2, 1993, pp. 145-152.