Volume 3, Number 2, Spring 2003

Engineering Technology Capstone Experience - An Industry Based Partnership

Andrew Otieno

Department of Technology,

Northern Illinois University, Dekalb, IL 60115

otieno@ceet.niu.edu

Clifford Mirman

Chair, Department of Technology,

Northern Illinois University, Dekalb, IL 60115

Mirman@ceet.niu.edu

Abstract

�The goal of any successful Capstone Senior Design course is to introduce students to real world problems and applications in engineering. Through curriculum, theory and applications are introduced; however, students have very limited industrial interaction. To develop this essential component, the Department of Technology at Northern Illinois University (NIU) has developed a senior year capstone experience that is based upon working with industry. The Department has taken advantage of its strategic location between the major metropolitan areas of Rockford and Chicago, Illinois, to develop active industrial partnerships that culminate in industrially based project work. These projects typically entail rigorous design and fabrication, and are multi-disciplinary in nature requiring knowledge in the areas of electrical, mechanical, and manufacturing. This year-long course is usually carried out by students working in teams of two to four individuals from the various disciplines and includes an oral and written technical presentation component. The participating companies provide funding to purchase components and fabricate the products, and also technical expertise and company insight. This paper details the structure of this course and the scope of the projects that have been undertaken.

Introduction

Capstone courses are used widely in engineering and technology programs to synthesize curricular outcomes in various subjects. As a standard practice, capstone design courses are offered in the senior years of technology and engineering degree programs, mainly to reinforce basic technical skills and to integrate and apply them to solve engineering problems systematically. However the manner in which this course is offered differs from one institution to another. Some institutions offer open-ended design problems, often culminating in an implementation or fabrication, but on projects selected by respective course instructors or faculty. Others do collaborate with industry to offer students real-world experience in solving engineering problems. On the other hand, quite a number of programs combine both industrially-or community-based projects with those instituted internally. Available literature suggests the majority of projects tend to be offered in collaboration with industry or the community1-6.

While it is common that the majority of the capstone senior design courses a year long, some are only a semester long2. There have been discussions and deliberations over whether the year long, industry sponsored projects offer a more comprehensive design experience than multiple, short-term mini projects, or projects without industry collaboration. At Idaho University for instance3, a study was carried out to investigate this and as a result, they adopted an approach that combines mini and industry oriented projects offered during the year. In other cases the organization of senior design capstone course may be dictated by the geographical location of a department with respect to major industrial sites. An example of such a situation is at Northern Illinois University (NIU). NIU is strategically located at the center of the two largest metropolitan areas of Illinois, Chicagoland and Rockford. Both these areas are characterized by having the largest concentration of manufacturing industries in the state. This scenario has presented an opportunity for the Department of Technology at NIU to develop active relationships with many companies in this region, and to have a very diverse Industrial Advisory Board. Based on inputs from its advisory board, the Department decided to modify their year long capstone course and introduced projects that are done in collaboration with industry7. This was done as part of an intensive curriculum reform that was initiated about three years ago. This paper presents the organization of this restructured program and some selected cases of projects that have been done in collaboration with industry. The paper also presents some of the experiences that both students and faculty have had over the years, and some recommendations.

Senior Capstone Course Structure

Over the past four years, the Engineering Technology senior capstone experience at Northern Illinois University has undergone several major revisions. This course is taken by senior students in the Electrical and Manufacturing Engineering Technology (EET and MET) emphasis within the department, and comprises two semesters work. In its present revised form, the capstone course has the following objectives;

� To provide senior students with an open-ended culminating experience

� To utilize a subset of skills which have been acquired through major courses

� To provide interaction with industry

� To emphasize interdisciplinary team-work

� Integration of technical oral and written presentation skills

� Provide an avenue where faculty can work with groups to provide explicit direction in areas of integration.

Incorporating these objectives into this course required input from faculty, students, and the departmental industrial advisory board members. This course is now structured such that the department chair serves as the project manager to all of the student teams. He ensures that projects are obtained from industry, and are inclusive of the components that are desirable for both EET and MET students. Typically, the solicitation process for projects is done in the summer. In addition, he acts as the course scheduler, contact person for company funding and questions, facilitator for ordering of materials, and most importantly, has the responsibility for student and team overall grading. The other important leadership task in this course falls to other faculty members who serve as the project advisors; one faculty member is assigned to each team, and they interact with the teams concerning the development and construction of the specific project. They are also involved in obtaining projects from industry and grading the student teams. By the end of the second week of class during the fall semester, the students are divided into teams, based upon the project needs, both in terms of skills and numbers.

In the completion of the design and construction tasks, the design teams are required to develop technical reports and proposals, both in written and oral form over the two semesters as follows:

� Initial project proposal � Due middle of first semester

� Written Project proposal� -� initial and final drafts � Due one week apart at the end of the first semester

� Oral presentation of design proposal � Presented at the end of the first semester

� Written final project report - initial and final drafts � Due one week apart at the end of the second semester

� Oral presentation of design proposal � Presented at the end of the second semester

� Final project poster presentation - Done prior to final oral presentation at the end of the second semester

� Final demonstration of project � Presented to faculty at the end of the second semester

Each presentation, which is developed by the groups, must include information that details the design and construction of the project. In addition, the students must also detail ethical and economic considerations in the project development and implementation.

Integration

In the senior capstone experience, students enrolling for that course must have attained �senior� status. At this stage of their studies, the typical student has knowledge of Calculus, Physics, and Chemistry. These basics are used in the Statics and Dynamics, Strength of Materials, Solid Modeling and Component design courses within the MET track. The practical oriented skills are acquired in the Fabrication and Machining courses, which also includes at an advanced stage, CNC machining. The EET track typically proceeds to advanced topics in electronics and applications to circuit design, micro-controllers and digital electronics. At some stage around the junior year both tracks usually take a course in programmable controllers (this is required for the manufacturing track). Prior to taking the senior design course the MET students normally take the automation course in which they learn how to integrate automation components. This involves sensors, vision systems, pneumatics, automatic identification techniques, robotics and the utilization of a controller such as a PLC to integrate these components into functional automation systems. The bodies of knowledge encompassed in these aforementioned areas are crucial to the successful undertaking of a senior design course.

The model project for this capstone course is sponsored by industry and requires a very rigorous integration of the manufacturing and electronics skills that have been developed in the curriculum. Every project requires some form of design, analysis, fabrication, and presentation. The students are expected to document their designs according to CAD standards, and demonstrate their ability to fabricate by producing the required parts using appropriate techniques. More often than not, fabrication of the project would be followed by some assembly, electrical installation, installation of motion components (whether pneumatic or electrical), and also installation of a controller (usually a PLC). Correct wiring, piping assembly and air supply/conditioning is critical, and the student teams must undertake these tasks correctly and safely. In addition, the students must program the PLC or whatever controller that is installed to complete the project.� The successful completion of the projects therefore requires integration of different bodies of knowledge and systems, from mechanical to electronics, at various levels ranging from a very simple load analysis to a complex finite element model and simulation of the project.� To accomplish this, the project manager and faculty project leader must ensure that the student teams posses the required skill balance. For instance, a project that is entirely electrical or electronics in nature may be assigned to student teams who are EET majors; while on the other hand, a project that requires both electronics and mechanical systems may be assigned to a mixed team of EET and MET majors. Student teams must hold consultations with their faculty, and in addition. report their progress on a weekly basis. Industry consultants/engineers in charge of the projects are also included in these meetings but on less regular basis. Students are expected to document and keep a log of the meetings they have held either with the faculty advisors or within their own teams.

Industry Role

Job openings for qualified manpower in the area of manufacturing especially in the Rockford and Chicago areas is very high and considerable growth is expected over the next eight years8,9. To meet this demand engineering colleges must strive to produce better trained graduates who posses the skills that are not only relevant but current. Our department is no exception and has continued to work toward these efforts. After numerous discussions with the departmental industrial advisory boards in the MET and EET programs, and with members of industry, the authors learned that there is a specific need for engineering technologists with an understanding of interdisciplinary teamwork, presentation skills, and design of components and systems. Upon examining the departmental curricula in the two engineering technology tracks in the department, it was found that these skill sets, which are required by industry, did not receive proper attention. In both programs, although the written presentation was adequate, the oral part was lacking. In addition, we determined that our students were learning the basics and processes; however, they never had the ability to apply this knowledge in open-ended design projects. A secondary outcome of this evaluation was the realization that our students were rarely exposed to interdisciplinary work or given the opportunity to work in teams. In addition, one other fact was evident; outside of the optional departmental internship experience there was very little student interaction with industry.

Several steps were taken by the department to address these shortcomings. First, the faculty undertook an effort to increase the numbers of courses in which presentation skills and teamwork were needed. Secondly, courses were added and altered to increase the teaching of design skills and open-ended project work in each area. However, the interdisciplinary work and industry interaction was still relatively absent from the curriculum. To remedy this problem, we turned to the engineering technology capstone experience. Over the past four years the departmental engineering technology (ET) senior projects course has evolved to include several of these important aspects that were lacking. The senior projects course was redesigned to require students to work in interdisciplinary teams to complete a two-semester open-ended design project. The underlying theme for the course and the projects themselves is that they must provide the student teams with the opportunity to develop numerous successful solutions. The course also further developed the students� presentation skills, through numerous oral and written presentations.� This course provides other additional benefits to our students through the interdisciplinary teamwork and the industrial involvement. Projects that are included in the course are provided by regional industry and include components from within the electrical, manufacturing, and mechanical disciplines. Each project is undertaken by teams comprised between two to four students, who are selected from the eligible students in the Electrical and Manufacturing programs. In the solution of the assigned problem, the students learn to integrate the disciplines in the solution to the various tasks that comprise the overall project.

The process of involving industry is usually started at the end of the summer. Companies in the Northern Illinois region are contacted to obtain projects. Apart from providing the ideas and funding to complete the projects, the companies also provide project leadership. This implies that as the students work with the faculty project advisor on a week-to-week basis, and they also work with members of the company regularly. This interaction ensures that the students develop workable designs, and they stay within the guidelines and policies of individual companies and course requirements, and adhere to timelines. The companies typically provide funding on the order of $2,000 � $4,000 (or more) to complete the projects. This funding allows the students to have an understanding of the process of ordering parts and components, and working with suppliers to ensure timely deliveries, and that components are compatible with each other. These are very valuable experiences which are needed in industry.

Case Studies of Selected Projects

In the last four years over 20 projects have been conducted in collaboration with industry. On the average there are between 30 and 40 students each year that are enrolled in the course. For instance this past semester (Fall 2002), the capstone course had 40 students enrolled, divided evenly between EET and MET. From this set, thirteen projects and teams were developed with the regional industry. The following is a description of four of the projects that been developed and undertaken over the entire period of curriculum restructuring.

Caterpillar Inc.

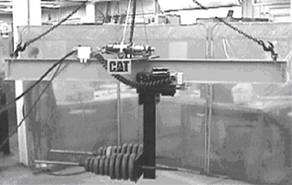

This project required the electrical and mechanical design and construction of a prototype for lifting and installing the tread system on a Challenger series tractor, as shown in figure 1a and 1b. The device had to be capable of preventing the rotation of the tread system by determining the center of rotation about two axes. The tread systems varied in weight and center of gravity. The student design, as shown below, is a scaled model that had to demonstrate the ability to keep the tread assembly level in two axes. The team comprised of three MET and one EET student. The group performed the stress calculations on the mechanical components such as cables and beams to determine maximum specified loads. The group then developed a two-axis motor controller that interfaced with an angular sensor, thus, allowing the determination of zero rotation and automatic compensation if rotation is detected.

![]()

�������

�������

Figure 1 � Caterpillar Challenger tractor (figure 1a) and tread lifting system (figure 1b).

Eaton Automotive Components

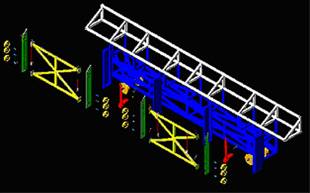

Over the past two years, Eaton has supplied three projects to the department, each of which consisted of developing automated processes needed to transport a thermal regulator between different manufacturing equipment. This is shown in figure 1a. The regulator, shown in figure 2a, is approximately one inch in height and � inch in diameter, and must move through four machines in its manufacturing process.� Each project required the student groups to integrate sensors, pneumatics, PLC�s, and various control aspects into a design that moved the part between a set of adjacent machines. In addition to developing interactive mechanical components, the group created a rigid support structure and user interface.

����������������

����������������

Figure 2 � Eaton thermal regulator transport system (figure 2a) and regulator (figure 2b).

General Electric Industrial Systems Division, Dekalb

This division of GE has supplied three projects in the past three years, each of which consisted of developing automated processes that solve specific ergonomic concerns. The first project (figure 3) involved the automation of handling steel posts needed to construct motor casings. In this case, an operator had to reach into a large container of material and deliver hundreds of posts to each of four processing stations. The design group developed a gantry system that used an electromagnet tied to an electric hoist. The lifting mechanism is controlled using proximity sensors and limit switches, all of which are controlled by a PLC. The second project was the development of a bar stock loading mechanism for supplying 24 foot steel round stock to a turret lathe. Figure 4, shows an exploded view of the student design. During operation, steel bundles weighing one ton are placed on to the top section, and thus, all aspects of the designed structure were analyzed using finite element modeling. The automation design consists of two gates that are secured in tracks to ensure linear travel, each actuated using a motor/screw drive mechanism. The operation is controlled using proximity sensors to determine when material is needed and when the input track is filled with material. The whole process is PLC controlled.

Figure 3 � General Electric motor casing delivery system

Figure 4 - General Electric bar stock loading system

Figure 5 � General Electric pallet removal/replacement project

The final project that has been undertaken with GE deals with another ergonomic concern, namely, the removal/installation of 50 pound carriers (aluminum pallets) on an automated assembly line. Prior to installation, the workers had to physically remove the heavy carriers, and they were experiencing lifting related injuries. To solve this complex problem, the design team utilized proximity and optical sensors, and pneumatic actuators to stop all pallet motion before the lift area, isolate the pallet in question, lift the pallet off of the track, and then push it onto a table for removal or inspection. The components of the system are shown in figure 5. As part of the project, the process had to be autonomous, and thus the process was controlled through a PLC with various user functions. The controller sequenced a similar operation to put the pallets back into operation.

Assessment Results

The College of Engineering and Engineering Technology (CEET) at NIU maintains a very rigorous assessment of every program through the office of the College Assessment Coordinator. For senior design projects, the assessment is done by a questionnaire survey completed by students, faculty, alumni and company representatives who are invited to attend the Senior Design Presentation day. A set of objectives that focus not only on ABET-TAC�s criteria10, but includes other outcomes specific to industry needs as well, were developed by the College to evaluate the senior design capstone course. Similar methods of assessment have also been applied elsewhere11-13. It should be noted that this assessment does not directly take into consideration the actual grades that the students obtained in the course, but emphasizes on the learning objectives and individual project success. Table 1 summarizes the objectives/outcomes of the Senior Design capstone course within the college.

Table 1 - CEET Objectives for Assessment of the Senior Design Courses

|

# |

Objective/Outcome |

# |

Objective/Outcome |

|

1 |

Application of� CEET coursework |

15 |

Value of project to underclassmen�s learning |

|

2 |

Applied problem solving in area of study |

16 |

Value of project to college�s reputation |

|

3 |

Applied problem solving outside area of study |

17 |

Apply knowledge of math science and engineering |

|

4 |

Increased awareness of engineering problems |

18 |

Design and conduct experiments � interpret data |

|

5 |

Learning/applying team principles |

19 |

Design system, component or process |

|

6 |

Analyzing and summarizing data in report |

20 |

Function on multi-disciplinary teams |

|

7 |

Applying presentation skills in professional setting |

21 |

Identify, formulate and solve engineering problems |

|

8 |

Expanded awareness of cultural diversity |

22 |

Understand professional and ethical responsibilities |

|

9 |

Worked across engineering disciplines |

23 |

Communicate Effectively |

|

10 |

Self-confidence skills |

24 |

Understand global and societal impact |

|

11 |

Clearly communicated problem, data and solution |

25 |

Engage in lifelong learning |

|

12 |

Perceived project of value to customer |

26 |

Knowledge of contemporary issues |

|

13 |

Perceived project of value to society |

27 |

Use techniques, skills, and tools of engineering practice |

|

14 |

Value of project to future professional success |

|

|

|

Responses for objectives 1 to 16 are:��������� 1. Little value, 2. Moderate Value and 3. Exceptional value Responses for objectives 17 to 27 are:���� 1. Disagree/Neither Agree nor Disagree, 2. Agree and 3. Strongly Agree. |

|||

Table 2 - Results of the Assessment for Spring 2002

|

Objective |

% of Respondents |

Objective |

% of Respondents |

Objective |

% of Respondents |

|||||||

|

1 |

�2 |

3 |

1 |

�2 |

3 |

1 |

�2 |

3 |

||||

|

1 |

10 |

40 |

50 |

10 |

0 |

30 |

70 |

19 |

10 |

60 |

30 |

|

|

2 |

0 |

45 |

50 |

11 |

5 |

32 |

63 |

20 |

25 |

40 |

35 |

|

|

3 |

10 |

40 |

50 |

12 |

10 |

35 |

55 |

21 |

10 |

45 |

45 |

|

|

4 |

0 |

55 |

45 |

13 |

20 |

35 |

45 |

22 |

45 |

35 |

20 |

|

|

5 |

5 |

35 |

60 |

14 |

5 |

35 |

60 |

23 |

40 |

40 |

20 |

|

|

6 |

0 |

65 |

35 |

15 |

0 |

50 |

50 |

24 |

30 |

55 |

15 |

|

|

7 |

0 |

45 |

55 |

16 |

0 |

40 |

60 |

25 |

25 |

45 |

30 |

|

|

8 |

30 |

55 |

15 |

17 |

15 |

50 |

35 |

26 |

20 |

70 |

10 |

|

|

9 |

0 |

60 |

40 |

18 |

30 |

55 |

15 |

27 |

0 |

70 |

30 |

|

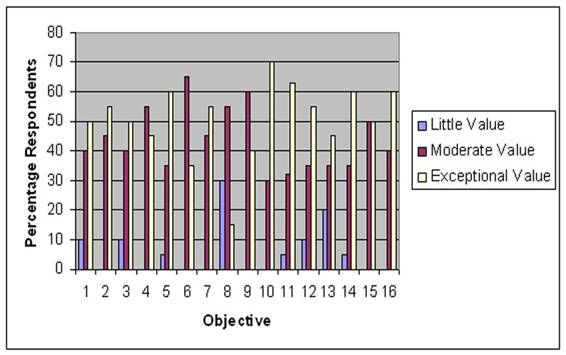

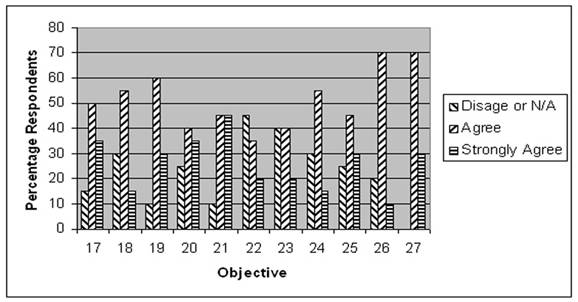

The results of the survey for the Spring 2002 semester are shown in table 2 above� . To illustrate how each of the objectives or outcomes were met, the results of the survey have been plotted in bar charts and these are shown in figures 6 and 7. From these results, there are a number of significant outcomes that arise from the collaboration we have developed with industry through this senior design course. The first and most important is the knowledge and experience gained by students. Over 50% of the respondents found the coursework, problem solving, data collection and management, and team skills were of exceptional value in implementing their projects. 74% of the respondents felt that the ability to function in multi-disciplinary teams was very important and that the capstone experience strengthened their skills in this area. At least 80% found that these projects were of moderate or exceptional value to society. Real life industry projects require the above mentioned abilities or skills and these results reinforce the fact that through senior design, our curriculum has achieved these outcomes. Through these projects, the students get first hand experience in implementing a real life industrial project in a timely fashion. They enhance their scientific and design skills with real life industry experience. This enriching exercise enables the students to integrate the isolated islands of skills they have obtained from various courses throughout their study, to carry out and implement a real life project successfully.

The second outcome is industry oriented. The collaborating industries are able to utilize students, with the help of faculty experts, to implement their projects without incurring large expenses that would have otherwise arisen from hiring consultants or subcontractors in the private sector. More than 50% of respondents feel the projects are of value either to the society or customer. 55% of the respondents felt that the projects were of exceptional value to the customer while another 45% felt they were of moderate value. Through industry partnership, there is a mutual outcome of promotion of interests. The result is that the Department and the College both get publicity and the students stand a much better chance of being hired by the companies in the partnership. On the other hand the Industry partners also enjoy publicity through presentations of these projects, and have contact with top quality graduates.

Other significant outcomes of this senior design experience include the fact that many of the people surveyed found that this experience had some impact in helping the students understand global or societal relevance in industry (70%), and that it helped the students engage in lifelong learning (75%). Many students however felt that the senior design projects did not help them understand professional and ethical responsibilities. In addition to this, a significant portion of the students (40%) still felt that the capstone design experience does not fulfill adequately the important objective of acquiring effective communication skills. These are two critical areas the department will address in the future offerings of the capstone design projects.

Figure 6

Figure 7

Figures 6 and 7. Assessment Results

Drawbacks and Lessons Learned

With any new or redesign of courses, there are usually obstacles to overcome and areas to improve upon. This engineering technology senior capstone course has proven to be no exception. In altering the course, the students were required to perform more tasks, put in more time in design, and spend more time on campus in labs applying the tools that they had learned in the prior coursework. Initially the students were reluctant, especially when they compared their experiences with those of their previous counterparts. However, as the years have gone by, the students have found out that often this is the only way the projects can be completed by the end of the semester and thus prolonged hours in the labs has become a standard practice for students enrolled in this class. The second main category of problems is faculty related. Previously, this course was offered for each discipline, was not interdisciplinary, and one faculty member taught it. At the present time, there are seven faculty members involved in these projects. Since this course is not part of the regular faculty loading, the faculty needed to be compensated. The Department therefore had to devise a way to obtain some funding to provide small stipends to each faculty member involved.

The initial task was to have companies on board to develop and sponsor the projects. For this, we turned to our departmental industrial advisory boards and local companies. During the first year of the new course one project was sponsored by industry, the second year five projects, the third year six projects, and this year (the fourth) there are nine projects sponsored by industry. The difficult part to selecting the projects was the development of project scope. Initially, many projects that were suggested did not meet the level of the student nor encompassed the desired skill sets. Over the years, this has been solved by the faculty and chair identifying a core group of companies that we work with, and working together to define suitable projects. The other problem dealt with project directions. It was determined after several years that companies need to be more involved in the initial design stages. This extra interaction puts more pressure on the faculty advisors to ensure that there is adequate flow of information, and that the students are not using the company representatives to work on the projects. Another difficulty in working with some companies is the understanding of the student learning aspects of the projects. Although many companies have the understanding that as students, their primary goal is to learn, and that the company might or might not get what they need out of the process, some companies feel that the money that is spent for the projects will produce a top quality, optimized, and automated process, even though at the start of the project, the faculty and chair discuss all the possible outcomes with the company representatives. In general, the revision of this important course has gone very smoothly, and, for the most part, all parties that have been involved are happy about the alterations.

Conclusions

Several outcomes of this collaborative venture have been discussed. One of the most significant is that our student learning experiences have been enhanced greatly by collaborating with industry to offer senior design projects. Three key skills identified earlier as very important for industry and yet lacked in our previous curriculum were interdisciplinary teamwork, presentation skills, and design of components and systems. Our goals were to introduce curricular changes and offer senior design projects that enabled students to improve upon these skills. The results of our assessment have shown that through industry collaboration these goals have been met. Through industry partnerships outreach activities have increased and the department is able to obtain alternative funding from industry to implement the senior design course. From this perspective, some of these partnerships have resulted in the department being able to get donations and sometimes cash grants from foundations of the various partners, and these the department has utilized in continuing to improve its curriculum and laboratory facilities. One of the main goals of the department is to produce top quality graduates who have understanding of engineering principles and can apply them effectively to solve industry problems. Indeed, these results attest to the fact that this goal has been met. Furthermore, through this course, there continues to be an increase in industry partnerships with our department and this is essential for us to continue providing an effective curriculum in the region.

References

[1]. Batzer, S.A. and Schmidt, W.F.� �Capstone design project coursework using the industrial short course format� Proceedings - Frontiers in Education Conference, v. 2, 2002, p. F2D/17-F2D/22.

[2]. Anwar, S. and Marchetti, D.� �Capstone design project for engineering technology students� Proceedings - Frontiers in Education Conference, v. 2, 2000, p. S2E/10-S2E/13.

[3]. Gershenson, J.A. and Blackketter, D.M. ��Discussion of mini projects and industry sponsored projects in capstone design classes� �ASEE Annual Conference Proceedings, v. 2, 1995, p. 1897-1904.

[4]. Werstler, D.E. ��Capstone course: Projects in industry�. ASEE Annual Conference Proceedings, v. 2, 1995, p 2437-2440.

[5]. Padmanabhan, G. and Katti, D. ��Using community-based projects in civil engineering capstone courses�. Journal of Professional Issues in Engineering Education and Practice, v. 128, n 1, 2002, p. 12-18.

[6]. Blanchard, S.M. and Rohrbach, R.P. ��Capstone engineering design projects to aid disabled persons�. Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology, v. 4, 2000, p. 2942-2944.

[7]. Otieno, A.W. and Mirman, C.R. � Machine Vision Applications within a Manufacturing Engineering Technology Program�. Proceedings of the 2002 ASEE Annual Conference and Exposition, Montreal, Quebec, June 16 � 19, 2002. Paper # 212

[8]. US Bureau of Labor Statistics, http://stats.bls.gov/oco/ocos223.htm , 4/2003.

[9] Illinois Department of Employment Security, http://lmi.ides.state.il.us , 4/2003.

[10] ABET ��Criteria for Accrediting Engineering Technology Programs, 2001-02�, http://www.abet.org/images/Criteria/tac_criteria_b.pdf, 10/2002.

[11] Doty, R..T. ��A Practice-based Senior Design Experience�, Proceedings of the 2002 ASEE Annual Conference and Exposition, Montreal, Quebec, June 16 � 19, 2002. Paper # 204.

[12] Rossetti, M.D., Cassady, C.R and Schneider, K.� �Assessing an Industry based IE Senior Design Course�, Proceedings of the 2002 ASEE Annual Conference and Exposition, Montreal, Quebec, June 16 � 19, 2002. Paper # 869.

[13] Sorensen, C.D., Magleby, S.P. and Todd, R.H., �Designing a senior capstone course to satisfy industrial customers�, Journal of Engineering Education, v. 82, no. 2, 1993, pp. 92-100.

Biography

Dr. ANDREW W. OTIENO received his Ph.D. from Leeds University, UK in 1994 and has been at NIU since August 2000. He has been actively involved in the restructuring of the MET curriculum and development of the Automation laboratory. His research is in the area of finite element modeling, machining processes, tool wear monitoring and structural health monitoring. He has experience in hardware/software interfacing with special applications in machine vision. He is a member of the ASEE and the SME.

Dr. CLIFFORD R. MIRMAN received his Ph.D. degree from the University of Illinois at Chicago in 1991. From 1991 until 1999, he was at Wilkes University�s Mechanical Engineering Department. He is currently Professor and Chair of the Department of Technology at NIU. His research areas are CAD, Finite-Element-Analysis, robotics and kinematics. He has numerous publications both in these areas and in innovative pedagogical approaches in undergraduate education. He has been actively involved in securing grants and writing publications. Dr. Mirman is dynamically involved in ASEE and SME.