Volume 6, Number 1, Fall

2005

Design and Development of a

Cost Effective Data Acquisition System Using PC’s Parallel Port

Abul K. M. Azad

Department of

Technology,

Northern

azad@ceet.niu.edu

Abstract

This paper describes

the design and development of a low-cost computer interfacing system. The system can be used between a PC and an

engineering system for data acquisition and control. The main features of the designed system are

low-cost, simple operation, flexible accommodation of various data acquisition

and control needs, and adaptability with Internet-based applications. To implement these concepts, the developed

system has the following features: a) interface ability with a PC through its

standard parallel port, b) ability to accept and provide various types of

inputs/outputs (analog and digital) with minimum hardware, c) user-friendly

graphical user interface (GUI) to monitor and control a data transfer between a

PC and an engineering system, and d) future extension capabilities through

maximizing the use of software in the development.

Introduction

The author and his

co-workers conducted a project towards the design and development of an

Internet-based physical laboratory facility.

The project has successfully shown that there is significant potential

for an Internet-based physical laboratory facility for educational, industrial,

and manufacturing fields.1, 2, 3

The benefits and effectiveness of the Internet-based laboratory facility

have also been highlighted by a number of other researchers.4, 5, 6, 7

Within the

developed facility, a commercially available Input/Output (I/O) card was used

inside a PC to act as a gateway between the experiment and the PC. The use of

commercially available I/O cards poses several drawbacks. These are

a) Cost: I/O cards are

relatively expensive, and their use requires additional cable and connection

boxes, which are expensive as well.

Considering the need for one I/O card for each experiment, the total

cost to set-up an Internet-based laboratory facility for a class would be quite

high.

b) Complex installation and

operation: Installation

of this I/O card needs access inside the PC along with the installation of a

suitable software driver. In some cases,

the installation needs expert help, as sometimes this task is beyond the scope

of a faculty and/or a student. All these

increase set-up time and also subsequent changes or modifications.

The above problems

hinder the wider use of an Internet-based laboratory facility as a part of a

regular academic laboratory course. To

overcome these problems, last summer, the author was awarded a project funded

by the Omron Electronics Foundation through the

This paper reports the design and

development of a computer interfacing system.

The system can be used as a stand-alone computer data acquisition and

control as well as a low-cost and simple alternative of an I/O card towards the

development of affordable Internet-based physical laboratory facilities. The designed system uses a computer’s

parallel port for its communication and provides a low-cost and effective means

of computer interfacing. After this

introduction, the first section describes the hardware and software

system. The second section compares the

developed system with the commercially available products along with a cost

analysis. These are followed by the

conclusion and a list of references.

System Description

The reported system has three main

components. These are hardware,

software, and GUI. The hardware part of this

project provides an electronic platform for transferring data between a PC and

an experiment through a PC’s parallel port, while the software provides a means

of controlling the data flow between a PC and an engineering system. The GUI provides the user with a tool for

adjusting various data acquisition parameters as well as monitoring the signal

waveform, which is being transferred.

Hardware

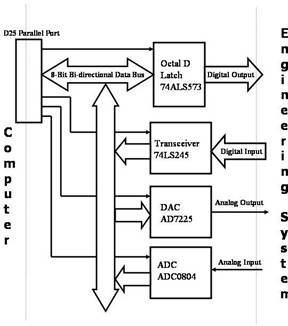

The hardware

system provides an interface between a PC and an engineering system through a

PC’s parallel port. A block diagram of

the hardware system is shown in Figure 1.

Figure 1: Block diagram of the hardware system

The left hand side

of the diagram is the host computer, which is to be used for data acquisition

and control while the right hand side of the diagram is the engineering system,

which needs to be controlled or from where data needs to be transferred (both

directions).

The system is

capable of handling digital and analog data for bi-directional transfers. In this way, one can send data from a PC to

operate an experiment or receive data from an experiment and subsequently store

them in a PC for further analysis.

Either a serial or

a parallel port of the PC could be used as the interfacing port. The parallel port was chosen, as this can

provide a means of transferring data in a parallel manner and hence facilitate

relatively high speed data transfer. The

hardware part of the developed system can be divided into three components:

digital data, analog data, and control signals.

a)

Digital

data: For the digital part,

there are two main tasks. One is to

provide a means of co-ordination in data transfer between a PC’s parallel port

and the experiment under consideration.

The second is to provide a buffer to safeguard the PC’s internal

hardware system. 8

b)

Analog

data: This system deals with

converting data from analog to digital (ADC) during the data acquisition

process and converting from digital to analog (DAC) while providing analog

output to an engineering system. The

hardware is designed to accept multiple inputs and outputs. The user can also change the data transfer

rate between a PC and an engineering system through the developed GUI.

c)

Control

signals: To keep track of

all these data transfers between a PC and an engineering system, there are some

control signals that need to be provided in a timely manner. The control signals are produced internal to

a PC in co-ordination with a user’s request through the GUI. 9

The outline of the parallel port interface circuit is given in Figure 1. The circuit consists of four main ICs. The functions of these ICs are described below:

74ALS573: Transparent Octal D-latch provides an 8-bit digital output. The outputs can be passed to an experiment as well as to a bank of LEDs for monitoring purposes. The Latch Enable pin of this chip is connected to the control port (bit-C0). This device is selected when the bit-C0 goes high, and the latch is disabled when the bit-C0 is low.

74LS245: Octal bi-directional transceiver provides an 8-bit digital input. This can be connected to a bank of status (digital) switches or any other device that can produce digital data. The pin Output Enable is connected to the bit-C1 of the control port. This device is enabled when the bit-C1 is low and disabled when the bit-C1 is high.

AD7225: DAC is used for providing analog output from a digital data stream provided from a PC. It consists of four 8-bit DAC with an output buffer amplifier. This DAC requires a reference voltage input. The output is taken from a particular channel depending upon the value of the address inputs. The control pin (bit-C3) of control port is connected to the /WR pin of this device. The conversion is done when the bit-C3 is low and is stopped when the bit-C3 is high.

ADC0804: 8- bit ADC is used to convert an analog output from an experiment to the digital while transferring this from an experiment to a PC. The conversion depends upon the read signal, which is being altered from one of the control lines of the parallel port to initiate the conversion process.

The parallel port has an 8-bit data bus, which is

connected to the PC’s internal data bus.

The

Table-1:

Bit status of the control port for various operations.

|

Operation |

C5 |

C4 |

/C3 |

C2 |

/C1 |

/C0 |

|

Output Digital Data (74ALS573) |

0 |

0 |

0 |

1 |

0 |

0 |

|

Input Digital Data (74LS245) |

1 |

0 |

0 |

1 |

1 |

1 |

|

Analog Output (through DAC) |

0 |

0 |

1 |

1 |

0 |

1 |

|

Analog Input (through ADC) |

1 |

0 |

0 |

0 |

0 |

1 |

Depending upon the function performed by different

command buttons within the GUI, the 8-bit data lines can be used as bi-directional

to transfer data between a PC and an experiment. A particular input or output can be selected

by placing specific values in the control register. Although the electronic components used are

capable of handling multiple inputs or outputs, their connection configuration

allows only one input or output signal to be active at any point in time. However, by using a suitable multiplexer

system, the capability of this system can be extended.

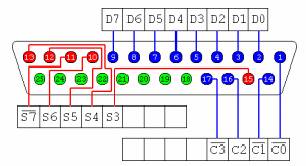

The parallel port of a PC is a 25-pin D-shaped female connector and is normally used for connecting a PC to a printer. It had a total of 12 digital outputs and 5 digital inputs accessed via three consecutive 8-bit ports in the processors’ I/O space. Eight output pins are accessed via the data port, 5 input pins are accessed via the status port, 4 output pins are accessed via the control port, and the remaining 8 pins are connected to the ground. Various enhanced versions of this parallel port have been introduced over the years: a) PS/2 (Bi-directional), b) enhanced parallel port, and c) extended capabilities port.

Figure 2: Pin configuration of a 25-pin D-shaped

connector

The original specification for the printer port allows data flow only in one direction. These enhanced versions of the printer port allow bi-directional transfer of data, yielding data acquisition and control through a printer port. The pin diagram and description of a 25-pin D-shaped connector are given in Figure 2.

The parallel port contains 8 data output pins (D0 through D7), 5 status input pins (S3 through S7), and 4 output control pins (C0 through C3). The pins with a bar on top are designated as active low. The detail description of each of these pins is given in Table-2. A - Indicates inverted logic, when + Indicates a positive logic.

Table-2: Specification of a 25-pin D-shaped

connector pins.

|

DB25 |

Sign |

Registration |

Type |

Asset |

Sense |

|

1 |

Control 0 |

C0 - |

Output |

Low |

Inverted |

|

2 |

Data 0 |

D0 |

Output |

High |

Direct |

|

3 |

Data 1 |

D1 |

Output |

High |

Direct |

|

4 |

Data 2 |

D2 |

Output |

High |

Direct |

|

5 |

Data 3 |

D3 |

Output |

High |

Direct |

|

6 |

Data 4 |

D4 |

Output |

High |

Direct |

|

7 |

Data 5 |

D5 |

Output |

High |

Direct |

|

8 |

Data a 6 |

D6 |

Output |

High |

Direct |

|

9 |

Data 7 |

D7 |

Output |

High |

Direct |

|

10 |

Status 6 |

S6+ |

Input |

High |

Direct |

|

11 |

Status 7 |

S7 - |

Input |

Low |

Inverted |

|

12 |

Status 5 |

S5+ |

Input |

High |

Direct |

|

13 |

Status 4 |

S4+ |

Input |

High |

Direct |

|

14 |

Control 1 |

C1 - |

Output |

Low |

Inverted |

|

15 |

Status 3 |

S3+ |

Input |

High |

Direct |

|

16 |

Control 2 |

C2+ |

Output |

High |

Direct |

|

17 |

Control 3 |

C3 - |

Output |

Low |

Inverted |

|

18-25 |

Ground |

- |

- |

- |

- |

There are three registers associated with every parallel port: a) data register, b) control register, and c) status register. Each of these registers is accessed with a specific address. The address allocation to each of these ports is as follows:

a) Data register: This register is 8-bits in size and can be addressed using the base address of the parallel port. The base address is either 3BC(hex) or 378(hex) depending upon which parallel port is in use.

b) Status register: It is an important register that is used to gather information from the peripheral device connected with the parallel port. The address for the status register is base address + 1 [3BC(hex) + 1 or 378(hex) + 1]. Only the five most significant bits are used from this address location.

c) Control register: The address for this register is base address + 2 [3BC(hex) + 2 or 378(hex) + 2]. It is used to control various functions of the peripheral connected with this parallel port. Only the four least significant bits from this address are used as a control register.

Software Usage

There is a number

of available high level software or software packages that can be used for the

purpose of this development. These are

C++, Java, Visual Basic, Matlab, and LabVIEW.

Considering the short development time, interface capability with future

web application, and targeted features for the GUI design, Visual Basic was

identified as the software tool for this project.10, 11 The developed software was used to access the

PC’s parallel port registers and can perform the following:

a) Collect incoming data (digital or analog)

stream and store them to a file on the PC’s hard disk;

b) Deliver a pre-programmed outgoing data

(digital or analog) stream from a file;

c) Provide control signals to perform the data transfer

task in a coordinated manner.

The software used for this

development has two specific purposes.

One is to develop a GUI as a front end for the user, and the other is to

perform the entire data collection and manipulation task as commanded by the

user through the GUI. A description of

the GUI will provide the capabilities of the system.

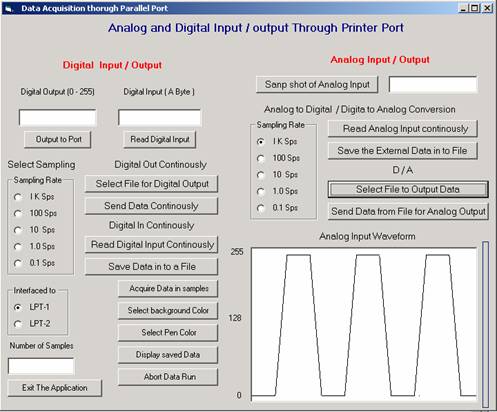

Graphical User Interface (GUI)

The GUI provides

the user with a means of controlling the data transfer process between a PC and

an engineering system. The front panel

of the GUI is shown in Figure 3. The

functionalities within the GUI are divided into three groups. The first one is for digital I/O, the second

one is for analog I/O, and the third one is the option buttons used to adjust

the graph display properties and the sampling rate. A figure window within the GUI (bottom right

corner) is used to display the analog and digital signals during a data

transfer process.

All the buttons

within the GUI are divided into two groups.

One is the command button group, and the other is the option button

group. The option buttons allow the user

to adjust certain properties of the GUI along with the sampling rate and choice

of panel color while the command buttons are used to perform a specific

operation.

Figure 3: The GUI

front panel.

Digital

Input/Output

The data transfer between a PC and an engineering system could be a

single value or a continuous data stream.

Single value to

output: For a single value output of 8-bit digital data,

the user needs to provide a decimal number (equivalent of a binary number) and

click on the “Output to Port” button.

This command button sends a specific binary value to the data register

as requested by the user. The data

register is 8-bit in size, and the range of the value can be from 0 to

255. The requested binary value can be

visually displayed through 8 LEDs connected with the data lines of the parallel

port.

Single value to

collect: For this operation, the user needs to click

on the “Read Digital Input” button.

This button reads a single digital byte and transfers the value to the

input register of the parallel port. The

collected data value will be subsequently displayed in a message box just above

the button. The data read could be the

status of a bank of switches or any other part of the engineering system that

produces a digital output.

Continuous

output: This function is

used to transfer a stream of 8-bit data from a PC to an experiment. The first step of this is to click on the “Select File for Digital Output” button. Upon activating, it

pops up a window for the user to select a pre-fabricated file with digital data

profile. After selecting a file, the

user needs to click on the “Send Data

Continuously” button. The data will then be passed to the

experiment through the interface hardware.

Continuous

input: This function reads digital data from an

experiment and stores them on a PC’s RAM at an interval determined by the

sampling rate. Various messages will be

popped out to inform the starting and end of a data acquisition process. A click on the “Read Digital Data Continuously” button will start the process.

A window will pop up to enter a file name. The data collected in this process will be

stored on this file for further analysis.

Analog

Input/Output

Single value to

collect: This operation reads a particular sample of

an analog signal through the ADC and places the value on a message window

around the top right corner of the GUI.

The command button for this operation is “Snap shot

of Analog Input.”

Continuous

output: This operation allows the system to deliver a

stream of analog data continuously from a PC.

The DAC comes into play for this operation. To initiate the process, the user needs to

click on the command button called “Select

File to Output Data.” Upon activating, it will pop up a window to

select a file from the PC’s hard disk.

This selected file must contain a series of data samples. Upon selecting a file, the entire data file

will be transferred to the PC’s RAM. To

complete the data transfer, the user needs to click on the command button

called “Send Data from file for Analog Output.”

Continuous

input: The analog input waveform applied to the ADC

will be sampled, and the 8-bit digital value will be read into the data

register of the parallel port. To

initiate the process, a user needs to click on the “Read Analog Input Continuously” command button. Various

messages will be popped out, informing the beginning and end of a data acquisition

process. The collected data will be

stored temporarily on the PC’s RAM to facilitate high speed data transfer. To save these data on a file, the user needs

to click on “Save the External Data into a File” button.

The user will then have an option to choose a file name and location,

where the collected data will be stored.

Option

Buttons

In addition to the digital and analog data transfer, the developed

interfacing system performs certain additional operations, which are described

in this section.

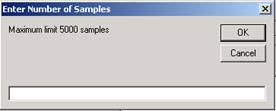

Acquire

specific amount of samples:

This command button is similar to the “Read

Analog Input Continuously” but

for a specific amount of samples. By

clicking this button, a window will pop out, where the user needs to enter the

number of samples (Figure 4). During

this operation, a pixel will be placed in the graph window area of the GUI

according the value of each data point.

Figure 4:

Sample number selection window.

Select

background color: A color palette window will pop out when a

user clicks on this button. The selected

color within the color palette will be set as the background color for the

picture part of the GUI.

Select pen

color: Activating this button will bring up the

color palette. The selected color is set as the pixel color pointed on the

picture part of the GUI.

Display saved

data: This command button, when activated, opens a

window to select a file name. The data

stored within the selected file will then be displayed in the display area of

the GUI.

Abort data run

and exit the application: This button is used to suspend a data

transfer process and will return the control to the GUI.

Interfaced to

LPT1 or LPT2: This option provides a choice to connect the

external circuitry to one of the two available printer ports.

Sampling rate: With

this option, a user can control the data transfer rate between a PC and an

engineering system by activating the appropriate radio button. The available sample rates are: 1000, 100,

10, 1, and 0.1 samples per second.

COMPARISON and COST ANALYSIS

One of the main

objectives of this project was to develop a cost effective interfacing system,

which can be used for Internet-based physical laboratory experiments as well as

a stand alone data acquisition system.

In addition to this, the system is developed with minimum hardware, and

most of the tasks are shifted within the software. This provides higher flexibility in terms of

user options and any future expansion.

The minimum hardware and software requirement is a PC with Pentium II

processor, 256MB of RAM, printer parallel port, and Visual Basic.

There is a range

of commercial products that are using computers’ PCI slot, parallel port, or

USB port for their interface system. At

the lower end, the price of these products is in the range of $100. In addition to these, one needs to acquire

the custom software package or develop their own software, using a suitable

high level language. The proposed

product cost is about $20, which includes hardware and software, and the cost

can be reduced further through mass production.

The software used for this project is Visual Basic and is usually

available within an engineering and engineering technology education

environment.

Conclusions

Design and development of a user

friendly low-cost data acquisition system have been presented. The system can easily be integrated with a PC

for data collection and control of an engineering system. The system has very little hardware and major

software components, which will ensure the user flexibility in data transfer

and future modification and/or upgrading.

A number of user-driven facilities have been incorporated within the

developed system so that the data can be transferred bi-directionally with

various options.

The developed hardware has three

components. These are a) digital data,

b) analog data, and c) control signals.

The digital data part is used to facilitate a buffer between a PC and an

experiment for digital data transfer while the analog data part provides a

means of converting an analog data to digital for a data collection process and

vice versa. The control signals are to

provide appropriate logic levels to the digital and analog parts of the system

and also facilitate co-ordination towards performing a desired data transfer

operation. Through the GUI, the user

initiates the generation of control signals by a PC’s hardware system.

The software part of this system

has two components. One is the GUI,

through which a user can choose a particular option and control the transfer

process for a given data transfer task.

The other part is the underlying code, which performs all the data

manipulation, storage and extraction of data, and the initiation of control

signals as instructed by a user. For

Internet friendliness and flexibility in design, Visual Basic is used for the

development of this GUI.

ACKNOWLEDGEMENT

The author expresses his gratitude to Omron Electronics

Foundation for funding this work. Also

thanks to Dr. Promod Vohra, Dean of

the

REFERENCES

[1] Azad, A. K. M., Otieno,

A., Ghrayeb, O. and Anand, N. (2003).

Internet Based Experiments for Physical Laboratory Set-up, ASEE

Annual Conference & Exposition (Information Systems Division),

[2] Ghrayeb, O., Azad, A. K. M., and Otieno, A. (2003). Internet Based Approach to Develop Remote Tool Monitoring System, 2003 Industrial Engineering Research Conference, Hilton Portland, Portland, Oregon, May 18 – 20.

[3] Azad, A. K. M., Otieno, and Ghrayeb, O. (2003).

Internet-Assisted Physical Laboratory Facility: Potential for Laboratory

Teaching and Industry Applications, International Journal of Engineering

Education (submitted).

[4] Mott, R.

L., Neff, G.P., Stratton, M.J., and Summers, D.C.S. (2002). Future

Directions for Mechanical Manufacturing, and Industrial Engineering Technology

Programs, Journal of Engineering

Technology, 19(1), pp.8-15.

[5] Machine

Vision Association of the Society of Manufacturing Engineers. 2000 Machine Vision Industry Trends Report,

2000. Available:

www.sme.org/cgi-bin/membhtml.pl?/mva/ 00mvatrends.htm&&&SME&>.

[6] Poindexter,

S. E. and Heck, B. S. (1991). Using the web in your courses: What can you

do? What should you do?, IEEE

Control Systems Magazine, 19,

pp.83-92.

[7] Catlin, A. C., et al., The SoftLAB experience: Building virtual laboratories for computational science, Available: http://www.cs.purdue.edu/research/cse/softlab /softlab-vlabs/softlab-framework/softlab_report/report.html, the site has last viewed on Monday, 13th of October 2003.

[8] Interfacing

to the

[9]

[10] Engdahl, T. (2000). How to use PC parallel port output, http://www.hut.fi/Misc/ Electronics/circuits/parallel output.html, and the site has last viewed on Monday, 13th of October 2003.

[11] Upper Canada Technologies, IOPORT and NTPORT for I/O hardware

access, www.uct.on.ca, and the site has last viewed on Monday, 13th

of October 2003.

BIOGRAPHICAL

INFORMATION

Abul K. M. Azad is an Assistant

Professor with the Department of Technology of