Volume 1, Number 2, Spring 2001

A Combined Stress Experiment Using a

Hacksaw

Marshall F. Coyle

Pennsylvania State University-York

1031 Edgecomb Ave.

York, PA 17403-3398

Email: mfc5@psu

Christal G. Keel

Pennsylvania State University-York

Email: christal@keel.org

ABSTRACT

This paper describes

a laboratory experiment that can be used to demonstrate combined stresses

to engineering students in Strength of Materials classes. A typical hand-held

hacksaw is used to illustrate combined normal stresses due to bending and

axial loading. A commercially available handsaw is loaded statically by tension

in the saw blade. The tensile load on the hacksaw blade results in both bending

and axial compressive stresses in the backbone of the hacksaw. This study

demonstrates the experimental technique of using strain gages to validate

an analytical solution, as well as the concept of creating and calibrating

a load transducer to measure the applied load. This paper presents details

on the analysis, experimental approach, and the results.

INTRODUCTION

The purpose of the experiment

is to demonstrate a basic concept of combine stresses that engineering students

typically encounter in their first Strength of Materials class. C-clamps,

coping saws, and hacksaws are popular examples of combine stress problems

presented in textbooks1, 2. This paper differs from other laboratory

experiments3, 4 using C-clamps in that its goal is to demonstrate

the validation of an analytical approach. This not only helps to further students’

understanding of combined stress but also demonstrates the experimental validation

portion of the design circle.

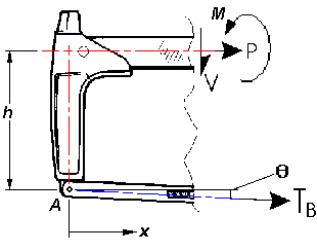

Figure 1 illustrates a

typically constructed hand-held hacksaw.

Figure

1: Typical Hacksaw.

The head, handle, and

backbone make up the frame of the hacksaw. The rigidity of the frame places the

blade in tension in order to prevent buckling due to the slenderness of the

blade. When a tensile force is applied to the blade, the head and handle

portions of the saw see a resulting tension. These forces produce both axial

compressive forces and bending forces in the backbone of the saw. A Stanley

contractor grade high-tension saw was chosen for this experiment, due to the

following characteristics:

- It has a quick blade tightener/release

mechanism that facilitates a rapid and easily repeatable loading and unloading

of the blade.

- The blade tension is adjustable up to

340 lb.

- The backbone consists of rectangular,

chrome-plated steel tubing that allows for the effective application of strain

gages.

- The distance between the centerline of

the saw blade and the backbone varies linearly, with the smaller distance

occurring at the head. This causes the bending moment to vary along the length

of the saw and makes for a more interesting analysis.

THEORY

Figure

2: Free body diagram of saw head and backbone.

Figure 2 is a Free

Body Diagram (FBD) of an arbitrary section taken through the saw. The shear

force (V), bending moment (M), and axial force (P) are all shown as being in the

positive direction for the standard beam convention. The blade is a two-force

member that produces a point load applied at point A. Since the blade sits in the frame at

a slight angle (q), the resultant force

will have X and Y components. The tensile force in the

blade (TB) is counteracted

by both an axial compressive force (P) and a shear force (V) in the backbone. This axial

compressive force serves to balance the horizontal component of the tensile

force (TB) while the shear

force (V) balances the vertical

component.

SFx =

0

(1)

P + TB *

cos(q) = 0

P = -TB *

cos(q)

SFy = 0

(2)

-V - TB * sin(q) = 0

V = -TB * sin(q)

Because both the

horizontal and vertical components of TB being applied at point A are eccentric to the axis of the

backbone a bending moment (M) is

produced. It is calculated as follows:

SMA = 0 (3)

M – P * h – V * x =

0

M = P * h + V * x

M = -TB * cos(q) * h – TB * sin(q) * x

where h is the vertical distance from point A to the neutral axis of the backbone

and x is the horizontal distance from

point A to the location of the

section. Figure 3 shows the cross-section of the backbone. The axial stress

(sA) in the backbone is

calculated by dividing the resultant compressive force (P) by the cross sectional area of the

backbone (A):

sA = P/ A

(4)

Figure

3: Cross-sectional drawing of the backbone.

The bending moment

produces a bending stress (sB), which is tensile on

the top and compressive on the bottom surfaces of the saw’s backbone. We can now

use the flexure formula to calculate the bending stresses:

sB = ± M * c /

Iz

(5)

where c is the distance from the neutral axis

to the outer surfaces of the backbone as illustrated in Figure 3, and IZ is the moment of inertia

about the Z-axis.

The strains on the top

(e

top) and the bottom

(e

bottom) of the backbone are

calculated by dividing the combined stresses by the modulus of elasticity (E = 29.0E6 psi for

steel):

e top =

(sB-top

+ sA) / E

(6)

e bottom

= (sB-bottom

+ sA) / E

(7)

EXPERIMENTAL VERIFICATION

I. Instrumentation:

The Stanley High-Tension

Hacksaw was instrumented with eight Measurements Group, Inc. EA-06-240LZ-120

Student Gages. The strain gage locations are shown in Figure 4 and listed

in Table 1.

Figure

4: Mounting locations of strain gages

Table

1: Gage Locations

|

Gage No. |

X

(in) |

Description |

|

1 |

6 |

Front of saw

blade |

|

2 |

6 |

Back of saw

blade |

|

3 |

2.164 |

Top of

backbone |

|

4 |

2.164 |

Bottom of

backbone |

|

5 |

6.111 |

Top of

backbone |

|

6 |

6.111 |

Bottom of

backbone |

|

7 |

9.017 |

Top of

backbone |

|

8 |

9.017 |

Bottom of

backbone |

The backbone is

instrumented with six strain gages, three along the top surface, and three along

the bottom surface of the backbone. Two strain gages are also located on the saw

blade, since it is used as a load transducer. The strain gages on the saw blade

were placed back-to-back on the front and backsides of the saw blade in order to

average out any effects due to bending in the saw blade. The gages were bonded

to the hacksaw with a Measurements Group, Inc. M-Bond 200 cyanoacrylate adhesive system. Strain gage

readings were taken using Measurements Group, Inc. P-3500 Portable Strain

Indicator with a SB-10 Switch and Balance Unit.

II. Load Transducer Calibration:

Calibration of the load

transducer was accomplished by acquiring strain gage readings for various

tensile loads. The instrumented saw blade was placed in a test frame shown

in Figure 5 and instrumented with a 0-5,000 kg dynamometer. The transducer

was loaded from 0 to 551 lb in 55.1 lb increments, and strain gage readings

were taken at each increment. A linear regression analysis was performed on

the calibration data. Figure 6 presents the results from the load transducer

calibration showing a plot of the load versus strain. It can be seen from

the plot that the behavior of the load transducer is linear.

Figure

5: Photograph of test frame set-up.

Figure 6: Load

Transducer Behavior.

III.

Experimental Procedure:

The saw blade (load

transducer) was positioned on the hacksaw attachment pins, which were located

on the head and handle of the saw as illustrated in Figure 1. The strain gage

balance unit was used to zero all the strain gage readings. Tension was then

applied to the saw blade by using the saw’s tensioning mechanism. The strain

gage readings from the loaded hacksaw were recorded, at which point the tension

was removed from the blade. Strain gage readings were taken after the load

was removed to determine instrumentation drift, which was found to be a maximum

of 6 µe. This test procedure

was replicated four times.

DISCUSSION OF RESULTS

There was good agreement

between the experimental and the analytical results for all four experimental

replications. The applied load varied from 304.5 to 306.7 lb among the replications,

which produced slightly different analytical and experimental results. The

difference between the analytical and experimental results was consistent

between the four replications. It varied less than 0.90 % for each location

between replications; therefore, only the results from one replication are

presented. The analytical and experimental results from one of the experiments

are tabulated in Table 2 and graphically shown in Figure 7.

Table 2: Analytical

and Experimental Results

|

Gage No. |

Analytical

Results |

Experimental

Strain |

Difference

(Analytical/ Experimental) | |||

|

Bending

Stress (psi) |

Axial

Stress (psi) |

Combined

Stress (psi) |

Strain | |||

|

3 |

35,408 |

-1,893 |

33,514 |

1,156 |

1,179 |

-1.98

% |

|

4 |

-35,408 |

-1,893 |

-37,301 |

-1,286 |

-1,256 |

-2.41

% |

|

5 |

36,971 |

-1,893 |

35,078 |

1,210 |

1,217 |

-0.61

% |

|

6 |

-36,971 |

-1,893 |

-38,864 |

-1,340 |

-1,353 |

0.95

% |

|

7 |

38,122 |

-1,893 |

36,229 |

1,249 |

1,247 |

0.18

% |

|

8 |

-38,122 |

-1,893 |

-40,015 |

-1,380 |

-1,374 |

-0.43

% |

Figure 7: Analytical and Experimental

Results

The results presented

in Table 2 and Figure 7 come from a test having a test load (TB) of 305.5 lb. Results

show there is good agreement between the analytical and experimental results.

The greatest difference was –2.41 %, which occurred at gage #4. The difference

between the analytical and experimental results is due to gage location measurements

that were taken. Errors in measurement h shown in Figure 2 will affect the

analytical solution the most.

SUMMARY

A simple hand-held hacksaw

that most people are probably familiar with was used to demonstrate the concepts

of axial, bending, and combined stresses and strains. This paper outlined

an analytical procedure for calculating the stresses and strains in the backbone

of a conventional hacksaw. The analytical results were then verified experimentally.

This paper gives details on the experimental procedure using strain gages

to validate the analytical solution. Finally, analytical and experimental

results are presented showing that there is good agreement between the two.

REFERENCES

1.

Applied Strength of Materials, 3rd edition, by Robert L. Mott, MacMillan Publishing,

pp. 421-422, 1996. ISBN 0-13-376278-5.

2.

Mechanics of Materials, 4th edition, by R.C. Hibbeler, Prentice Hall, pp.

434-437, 2000. ISBN 0-13-016467-4.

3.

Of Clamps & Spring & Things:

http://www.measurementsgroup.com/guide/notebook/e22/e22.htm,

Measurements Group, Inc., last accessed April 17, 2001.

4.

A Strength of Materials Laboratory

Experiment: http://et.nmsu.edu/~etti/spring98/mechanical/magill/magill.html,

Michael

A. Magill, Ph.D., P.E., last accessed April 17,

2001.