Volume 4, Number 2, Spring 2004

FlexPDEÒ: A Useful Tool for the Numerical Solution of Partial

Differential Equations

Wael M. G. Ibrahim

Computer Electronics Department,

Email: wibrahim@ecpi.edu

ABSTRACT

In this paper, the

author reports on the use of commercially available software, FlexPDEÒ from PDE Solutions, to numerically solve the

parabolic two-temperature model (TTM). Ultrafast

time-resolved pump-probe studies of energy relaxation and transport in

polycrystalline gold films are conducted. The experimental results are analyzed

within the framework of the two-temperature model (TTM). A description of the problem descriptor file and a

comparison of the model results to the experimental ones are presented. Model

predictions show good agreement with the transient thermoreflectivity

experiments on thin gold films.

INTRODUCTION

The study of laser-material interaction is of

utmost importance for many industrial processes such as laser annealing, thin

film deposition, and micro-machining. Over the past decade, many reports are

available in the literature on experimental investigations of non-equilibrium

electron dynamics in metals carried out using several techniques. Picosecond and femtosecond

time-resolved thermomodulation reflectivity and transmissivity (TTR)1-4, surface-Plasmon resonance (SPP)5,6, time-resolved

two-photon photo-emission(TPPE)7,8,9 and recently single-photon

photo-emission10,11 are some of these techniques.

When

a laser pulse, of a duration less than or comparable to the electron-phonon

energy-loss time, is used to excite a metal surface, a transient

non-equilibrium occurs between the effective electron temperature, Te,

and the lattice temperature, Tl.

Electron-electron scattering, electron-phonon scattering, and heat transport

determine the subsequent equilibration of the electron gas and the lattice. Due

to the large electron population, electron-electron interactions were assumed

to be fast enough to thermalize the electron gas on a

time scale shorter than the laser pulse duration, permitting a simple modeling

of the electron thermalization dynamics using the

classical Two-Temperature Model (TTM) which was initially proposed by Anisimov 12 as

(1)

(1)

Where, k is the thermal conductivity (W/mK),

Ce is the electron heat capacity (J/m3K),

Cl is the lattice heat capacity (J/m3K),

Te is the electron effective temperature (K), Tl

is the lattice effective temperature (K), and G is the electron-phonon coupling

coefficient (W/m3K).

Due

to the nonlinear nature of the TTM, an analytical solution is not possible, and

hence it has to be solved numerically. Several groups13-18 reporting

on their studies of the electron dynamics in metals had to develop their own

numerical procedure for the solution of the TTM or use existing subroutines in

the IMSL libraries. In both cases, this requires familiarity with the mathematical

algorithms and programming languages involved in the modeling. Not only that,

but the code produced has to be unambiguous and structured in a clear manner as

to allow any future users not involved in the original development to be able

to modify or at least use the code. The programmer should also provide means

for data obtained through the simulation to be properly displayed. Thus, the

development time for the software is rather long.

FlexPDEÒ, on the other hand, offers

a common platform that is not only capable of numerically solving the coupled

nonlinear equations but requires little knowledge from the user about

programming other than properly defining the physical problem. In this paper,

we present a description of the problem descriptor file used to define the

physical problem and compare the results of the numerical solution to our

experimental results.

MODELING

Conventional programming languages utilize

procedural problem descriptors? in which the user

defines a sequence of steps to be executed in order to get to the solution. FlexPDEÒ, however, only requires the

user to relate the various components of the system to one another to form what

is known as a relational problem descriptor. Thus, a partial differential

equations system, following the user’s description, is turned into a finite

element model. FlexPDEÒsolves the system, and the

results are presented graphically according to the specifications of the user.

In

preparing the problem descriptor file, the user needs only to worry about the

physical problem description,such as the set of

partial differential equations, the variables, the system coordinates, initial

values, boundary conditions, and finally the time domain over which the

solution is sought. Several sections, each identified by a header, constitute

the problem descriptor file. Some of the most frequently used sections are

illustrated in Figure 1 below.

|

TITLE

' ' SELECT COORDINATES VARIABLES DEFINITIONS INITIAL

VALUES EQUATIONS CONSTRAINTS BOUNDARIES TIME MONITORS PLOTS HISTORIES END Figure. 1. Main section headings of the problem descriptor

file. |

Even

though interlaced, these sections can be considered as divided into two main

categories. The first one controls the program functionality as to the solution

method, the coordinate system to be used, the grid size, etc.

This

first category includes:

- TITLE in which a descriptive

label for the problem is given.

- SELECT provides the user with

an override to some of the default behavior of FlexPDE

such as the relative PDE error, grid size, choice

of Cranck-Nicholson, Galerkin

or backward implicit schemes.

- COORDINATES is where

the user defines the coordinate system to be used.

- PLOTS give the user a choice

of the desired graphical output.These may be any

combination of CONTOUR, SURFACE, ELEVATION or VECTOR plots19.

The

second category involves the definition of the physical problem itself. In

these sections, the user states the partial differential equation system, the

variables associated with it, and finally the initial and boundary conditions.

The

section headings are as follows:

- VARIABLES is the section where the

dependent variables are named.

- DEFINITIONS is used to declare the

numerical constants.

- EQUATIONS

is where each variable is

associated with a partial differential equation.

- INITIALVALUES provide the

starting values for nonlinear or time-dependent problems.

- BOUNDARIES describe the

geometry by walking the perimeter of the domain, stringing together line

or arc segments to bound the figure.

- TIME section is used in time-dependent

problems to specify a time range over which the problem is to be solved19.

FlexPDE® constitutes a complete

problem -solving environment as it performs the entire range of functions

necessary to solve partial differential equation systems19. The

versatility of FlexPDE® relies on the

ability to define the geometrical domain of the problem by a set of line and

arc segments. In our model, thermal insulation boundary conditions were used so

as to constrain the sides of the sample to the ambient temperature and neglect

any heat losses from the back surface. The electron and lattice temperature

were used as the two variables for which the equations are to be solved. The initial

conditions for the electron and the lattice systems were chosen as Te

= Tl = Ta =300 K. The physical

properties of gold, Table 1, and the source term were specified in the Definitions

section.

The

results of the model are then exported to a text file that can be read by our

data presentation software for comparison with the experimental results.

However, the user has the ability, within FlexPDE®,

to generate a number of graphical displays of the results through plots,

surface, or contour graphs. Surface graphs can be rotated in 3-D which provides

the user with a flexible way to view the progress of the solution on a more

complex structure. FlexPDE® also supports

the possibility of exporting the results to different visualization software

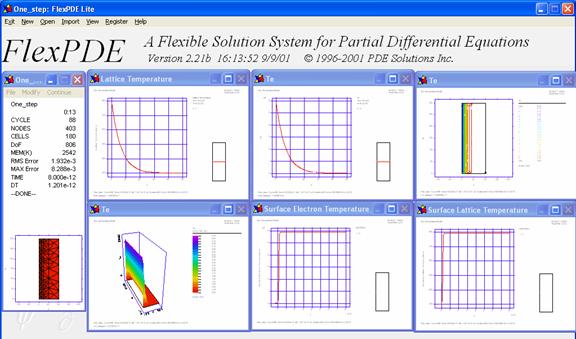

such as Tecplot®. Figure 2 shows a

screenshot of the FlexPDE window which is subdivided

into several windows displaying the different variables specified by the user,

e.g., lattice temperature and electron temperature.

Figure 2. A

screenshot of FlexPDE

Table 1. Room temperature

properties of gold

|

|

Au |

|

|

Measured ‘G’ a |

2.8 ± 0.5 |

x 1016 W m-3 K |

|

Melting point b |

1063 |

°C |

|

Thermal conductivity ko b |

315 |

W m-1 K |

|

Electron heat capacity Ce

b |

2.1 |

x 104 J m-3 K-1 |

|

Lattice heat capacity Cl b |

2.5 |

x 106 J m-3 K-1 |

a From data in Ref. [13].

b Ref. [20].

EXPERIMENTAL RESULTS

Experimental investigations of ultrafast

laser heating of thin gold films were performed using an ultrashort

pulse laser system at the Center for Materials Research (CMR) at Norfolk State

University (NSU). The laser system consisted of a commercial Ti:Sapphire (Mira 900) laser and a

regenerative amplifier (RegA 9000) from

Coherent. The input to the experimental

setup21 consisted of ~500mW pulses at 250 KHz repetition rate with a

FWHM <200fs.The basic arrangement, Figure 3, is that of a collinear

pump-probe setup.

Figure 3. Collinear pump-probe experiment.

The detection of the thermoreflectivity

signal was achieved by modulating the pump beam intensity at a fixed frequency, W, and using a phase-sensitive detection scheme (lock-in). Differential

detection was used so as to cancel out the fluctuations of the RegA output, leaving only the signal caused by the chopped

pump beam. Thus, the lock-in detects modulations in the received probe

intensity that is caused only by the effect of the pump on the sample. LabviewÒ from National Instruments was used as the control

platform for the stage and the data acquisition.

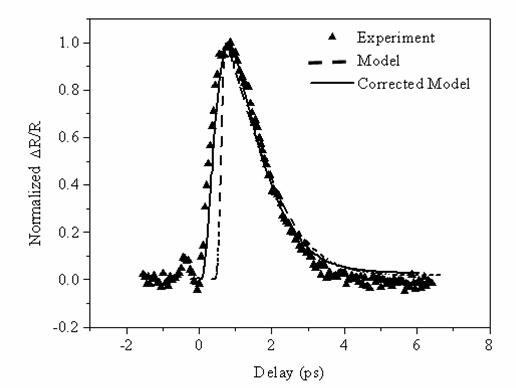

Figure 4 shows a comparison between the

time–resolved ΔR/R, where R

is the reflectivity, of an 400 A° Au film and the predictions

of the TTM during 120 fs laser pulse heating.

Predictions from the TTM model show good agreement with the experimental

results. The discrepancy in the initial rise is attributed to the assumption of

an instantaneous thermalization of the electron gas

on a time scale shorter than the laser pulse duration. Convolution effects have

also been known to affect the rise time of the thermomodulation

signals. These effects have been corrected22, and the results are

also shown in Figure 4.

Figure 4. Comparison

between the experimental results, the TTM, and the model taking into effect

convolution and thermalization effects for Au 40-nm, laser

incident fluence was

2.7 mJ cm-2

CONCLUSION

FlexPDE®

was used to numerically solve the TTM describing the ultrafast

dynamics of optically excited electrons in thin metal films under laser

heating. Using FlexPDE® to solve the TTM

greatly reduced software development overheads and improved flexibility.

Offering noncomputer specialists an easy means to

model their experiment, FlexPDE® has much

to offer to the experimenter in the investigation of energy transfer in single

or multilayer metals during short pulse laser heating. FlexPDE version 4.0 is

available in three license configurations. The evaluation and the student configuration

are free. A vast number of meaningful problems of science and engineering can

be addressed within the limits of these configurations19. The professional

configuration offers the full power of FlexPDE

version 4. It has effectively unlimited mesh size and unlimited number of

simultaneous equations19. Reducing software development time and

improving flexibility, FlexPDE® proved to

be a valuable tool in modeling heat transfer mechanisms in thin metal films

under ultrafast laser irradiation.

ACKNOWLDGMENT

The author wishes to acknowledge Dr. Carl E. Bonner,

Jr. for the use of the femtosecond laser at

REFERENCES

[1] G. L. Eesley,

“Observation of Nonequilibrium

Electron Heating in Copper,” Physical Review Letters, Vol. 51, 1983, pp. 2140-2143.

[2] G. L. Eesley, “Generation of nonequilibrium

electron and lattice temperatures in copper by picosecond

laser pulses,” Physical Review B, Vol. 33, 1986, pp. 2144-2151.

[3] H.

E. Elsayed-Ali, T. B. Norris, M. A. Pessot, and G. A. Mourou, “

[4] H. E. Elsayed-Ali, and T. Juhasz, “Femtosecond time-resolved thermomodulation of thin gold films with different crystal

structures,” Physical Review B, Vol. 47, 1993, pp. 13599-13610.

[5]

H. Inouye, K. Tanaka, I. Yanahashi, K. Hirao, “Ultrafast dynamics of nonequilibrium electrons in a gold nanoparticle

system,” Physical Review B, Vol. 57, 1998, pp. 11334- 11340.

[6]

R. H. M. Groeneveld, R. Sprik and Ad Lagendijk, “ Femtosecond spectroscopy of electron-electron and electron-phonon

energy relaxation in Ag and Au,” Physical

Review B, Vol. 51, No. 17, 1995,

pp 11433-11445.

[7] J. Cao,

Y. Gao, H. E. Elsayed-Ali, D. A, Mantell, “Femtosecond photoemission study of ultrafast

electron dynamics on Cu(100),” Physical Review B, Vol. 56, 1997, pp.1099-1102.

[8] S. Ogawa, H. Nagano, and H. Petek, “Optical Dephasing in Cu(111) Measured by Interferometric

Two-Photon

[9] S. Ogawa, H. Nagano, H. Petek, “Hot-electron

dynamics at Cu(100), Cu(110), and Cu(111) surfaces: Comparison of experiment

with Fermi-liquid theory,” Physical Review B,

Vol. 55, 1997,

pp.10869-10877.

[10] S.D. Brorson, A. Kazeroonian, J. S. Moodera, D. W.

Face, T. K. Cheng, E. P. Ippen,

M. S. Dresselhaus, and G. Dresselhaus, “Femtosecond

room-temperature measurement of the electron-phonon coupling constant gamma

in metallic superconductors,” Physical

Review Letters, Vol. 64,

1990, pp. 2172-2175.

[11]

R. Rosei,

and D. W. Lynch, “Thermomodulation Spectra of Al, Au,

and Cu,” Physical Review B, Vol. 5, 1972, pp. 3883-3894.

[12] S.I. Anisimov, B. L. Kapelovich, and T. LO. Perelman, “Electron emission from metal surfaces exposed to ultrashort

laser pulses,” Soviet Physics – JETP, Vol. 39,

1974, pp. 375-377.

[13] T. Q. Qiu, C. L. Tien, “ Short-pulse laser

heating on metals,” International

Journal of Heat and mass

Transfer, Vol. 35,

1992, pp. 719-726.

[14]

T. Q. Qiu,

C. L. Tien, “Heat

transfer mechanisms during Short-pulse laser heating of metals ,”Journal of Heat Transfer, Vol. 115, 1993, pp. 835-841.

[15] T. Q. Qiu,

C. L. Tien“ Femtosecond laser heating of multi-layer metals_ II. Experiments,”

International

Journal of Heat and mass Transfer,Vol. 37, 1994, pp. 2789-2797.

[16] C. K. Sun, F. Vallee,, L. Acioli,

E. P. Ippen, and J. Fujimoto, “Femtosecond tunable

measurement of electron thermalization in gold,”

Physical

Review B 50, 1994, p. 15337.

[17] W.

S. Fann, R. Storz, H. W. K.

Tom, and J. Bokor, “Direct measurement of nonequilibrium

electron-energy distributions in subpicosecond

laser-heated gold films,” Physical Review Letters, Vol. 68, 1992, pp. 2834-2837.

[18] W. S. Fann, R. Storz, H. W. K. Tom, and J. Bokor,

“Electron Thermalization in Gold,” Physical Review B 46, 1992, pp. 13592-13595.

[19]

FlexPDE®,

http://www.pdesolutions.com, User

Manual, PDE Solutions Inc.,

[20] Gray, D.E., ed., American Institute of

Physics Handbook, 3rd ed.,

[21] Wael M.

G. Ibrahim, H. ElSayed-Ali, C. E. Bonner, and M.

Shinn, “Ultrafast investigation of electron

dynamics in multi-layer metals,” International Journal of Heat and Mass Transfer, Vol. 47, No. 10-11,

2004, pp. 2261-2268.

[22] Wael

M. G. Ibrahim: Ph.D Thesis, “Study of Non-equilibrium Electron dynamics in

Metals,”