Undergraduate

Teaching of Biomaterials

Department of Mechanical

Engineering,

Universidad de las Americas-Puebla,

Santa Catarina Martir, Puebla 72820, Mexico

Email: sudhakar_vadiraja@yahoo.com

Tadeusz Majewski

Department of Mechanical

Engineering,

Universidad de las Americas-Puebla,

Santa Catarina Martir, Puebla 72820, Mexico

Email: majewski@mail.udlap.mx

ABSTRACT

This paper discusses some of the relevant teaching methodologies and supplemental experimental tools for studying biomaterials. Austenitic Stainless Steel (316L grade) and Vitallium-2000 Plus (Cobalt-Chrome alloy) metallic biomaterials that are commonly in Artificial Hip Joint (AHJ) and Partial Orthodontic Dentures (POD), respectively, are studied in particular. Teaching methods discussed in this paper include a discussion-model approach, lecture-quiz approach, and learning outside the classroom approach. Failure-analysis approaches/methods include destructive and non-destructive tests. Specific experimental procedures for destructive tests (namely, tensile test, hardness, and charpy impact toughness) are developed to suit the exact biomaterial geometries. The present detailed and systematic studies bring out the practically useful classroom teaching and supplemental experimental approaches/tools for understanding and analyzing failures in any given biomaterial. Specific methods/procedures are also discussed to evaluate the course by assessing students’ performance and effectiveness of the course.

INTRODUCTION

This course is proposed to be introduced as an undergraduate interdisciplinary course for students with mechanical, materials science, medical engineering, chemical engineering, and biochemistry backgrounds. Biomaterials are nonviable materials used in a medical device intended to interact with biological systems. One of the prime requirements is biocompatibility, that is, the ability of a material to perform with an appropriate response in a specific application.1 Biomaterials include implant devices, drug delivery, biosensors, bioseparation, cell/tissue/organ culture, animal husbandry, aquaculture and the biochip. In all these cases, the common theme is interaction between biosystem and synthetic or modified natural materials.

The stainless steel alloy presently recommended for device

manufacture is the American Iron and Steel Institute (AISI) type 316L. The

exact composition may vary slightly relative to the casting or forging variant;

however, both forms are derived from the very common 18-8 stainless steel alloy

(18% chromium, 8% nickel) used in tableware and other commercial applications. The

cleanliness or purity of the refined implant stainless steel alloy may influence

greatly the corrosion resistance and mechanical properties. It is estimated

from retrieval studies that stainless steel alloys constitute approximately 60%

of the implants used in the

The introduction of Vitallium-2000 Plus material provides physical and mechanical properties never before attainable in chrome cobalt alloys. Vitallium-2000 Plus incorporates a controlled nitrogen addition during the con-cast process, which results in a yield and tensile strength and elongation higher than any other chrome cobalt alloy on the market. The improved physical properties provide extraordinary strength and unprecedented fracture resistance while allowing for smaller, lighter, more delicate partial frameworks. Vitallium-2000 Plus also has increased flexibility, without deformation or fracture, allowing for excellent adjustability similar to that of gold. Vitallium-2000 Plus is the premium alloy of choice for the ultimate partial denture.

This paper discusses the relevant teaching methods and also the supplemental experimental procedures to learn and gain hands-on experience on biomaterials, including some aspects of bioengineering and biomechanics. A study on micromechanics of fracture and related failure analysis approaches is very important to understand and evaluate the failure behavior of biomaterials.

UNDERGRADUATE COURSE

ON BIOMATERIALS AND ITS ROLE IN THE CURRICULUM

A typical biomaterial

course taught for the undergraduate students with special emphasis on micromechanics

of fracture and failure analysis approaches includes the following contents:

namely, course objectives, learning objectives, and methodology for teaching.

This course is offered as an elective for undergraduate students. The students

studying this course usually have a preliminary background in materials science,

medical science, manufacturing process, and basic mechanics. The typical number

of students in this course is 15 to 20. This course is very useful for preparing

mechanical/materials/biomedical engineers with sound knowledge of specialty

materials like biomaterials.

COURSE OBJECTIVES

Material/biomaterial selection is a challenging task in developing

a medical device. Many factors, often competing, need to be considered. They

include mechanical properties, biocompatibility, microstructure, micromechanics

of fracture, production costs, and ease of manufacturing apart from others

that may be important depending on a specific situation. This course familiarizes

the student with relevant material issues and highlights the process for matching

material performance with the design of a particular medical device. The students’

knowledge of biomaterials will be increased, and an appreciation for the relationships

between a material’s structure, its properties, and the implementation of

properties to achieve a desired functionality will be developed. Failure analysis

approaches are discussed (theory and practice) to enhance students’ knowledge

on biomaterials.

LEARNING OBJECTIVES

Upon successful completion of this course, the student will be able to

COURSE METHODOLOGY

Instruction is followed by an interactive, lecture-style

format. Inclusion of a series of guest lecturers increases the breadth of

knowledge presented. The first half of the semester concentrates on basic mechanical testing, microstructure including

micromechanics of fracture and on the properties of materials, including dental

materials and biological tissues. The

second half of the semester is more applications oriented, with particular

emphasis on understanding the usage of metallic implants. Failure analysis

is studied in greater detail with a special emphasis on case studies.

TOPICS OF THE COURSE/

LECTURE COURSES ON BIOMATERIALS

Various

course lectures/lecture topics covered in the undergraduate course on

biomaterials are detailed below. Typically, this course is taught over a 14-week

period in a semester.

1. INTRODUCTION TO MATERIALS

SCIENCE (9 lecture hours)

1.1 Fundamental concepts of materials science: properties,

microstructure, stability and processing, and biocompatibility

1.2 Biomaterials - medical fundamentals for the application of biomaterials

1.3 Metals, ceramics, polymers, composites biomaterials

1.4 Medical terminologies,

interactions between artificial materials and human tissue.

1.5 Characterization of materials: techniques and methodology, mechanical

properties,

wear resistance, and corrosion testing

2. PROPERTIES OF MEDICAL

BIOMATERIALS (10 lecture hours)

2.1 Metallic biomaterials

Mechanical properties, microstructure characterization

of

· Stainless steel

· Titanium alloys

· Newer titanium alloys

· Cobalt-chrome (vitallium) alloys

2.2 Polymeric

biomaterials

Mechanical properties, microstructural

characterization of

· Biodegradable polymers

· Inert polymers

2.3 Ceramics

biomaterials

Preparation, microstructure, mechanical and biological properties of

· Bioglasses

and bioactive glass ceramics: alumina

· Zirconia

· Bioglass

· Diamond-like carbon

2.4

Materials for dental restorations

Medical fundamentals for dentistry,

dental restorative materials, and oral implantology

3. FUNDAMENTS OF BIOMEDICINE (5 lecture hours including guest lectures)

3.1 Cytology: histology and immunology

applied to biomaterials

3.2 Properties of natural tissues: biomechanics

4. TISSUE-BIOMATERIAL

INTERACTIONS (7 lecture hours)

4.1 Tissue-biomaterial interactions

4.2 Adsorption of proteins

4.3 Biocompatibility and toxicology

4.4 Role of microstructure properties in the choice of biomaterials and design of artificial organs, implants, and prostheses.

4.5 Fixation methods and bioactive

materials

5. APPLICATIONS OF BIOMATERIALS

(8 lecture hours)

5.1 Implants for soft tissues

5.2 Implants for hard tissues

5.3 Dental materials

5.4 Blood-related

materials

5.5 Ophthalmologic

implants

5.6 Drug-release

devices

5.7 Biosensors

5.8 Sterilization

6. FAILURE ANALYSIS OF BIOMATERIALS:

Typical case

studies (3 lecture hours)

The students are graded based on their performance in the following way:

Test #1: 15%

Test #2: 15%

Test #3: 15%

Quiz: 15%

Project: 15%

Finals: 25%

TOTAL:100

DISCUSSION-MODEL APPROACH

IN TEACHING BIOMATERIALS

A discussion model is used to understand and discuss the topic “micromechanics of fracture and failure analysis techniques” used for biomaterials. This model aims to make small-group discussion more meaningful and effective in light of limited spatial resources and growing class sizes. Typical class size is 20. The course structure involved two hour class discussions that complement three hour weekly lectures. During each session, the 20-student discussion group is divided into subgroups of five students; each sub-group is given one or two topics (under which specific problems are highlighted) to discuss. After 15 minutes of preparation, the sub-groups are encouraged to debate/discuss the issues with each other; the professor acts as a discussion facilitator and summarizes key issues raised during the two hour discussion.

LECTURE QUIZ APPROACH

Lecture

quizzes are introduced as a continual assessment component. Typically, 10-15

short questions (demanding specific answers) in the form of multiple-choice, true/false

or computation are asked in each lecture quiz. Students are allowed to discuss

the questions and hand in the answers in small groups. The main aim of the

lecture quiz is to give the lecturer a better gauge of whether the students

have grasped the main concept taught in each lecture on specialty topics like

biomaterials. It also promotes cooperative learning among the students as well

as allows them to relate to and reflect instantly on what they have just

learned.

LEARNING OUTSIDE THE CLASSROOM (ESPECIALLY FOR LEARNING-FAILURE-ANALYSIS APPROACHES)

This technique provides the opportunities for students to

learn outside the classroom, apply theoretical concepts learnt in class, and

have these concepts challenged through practical application. This practice is

very vital, especially for learning failure-analysis techniques. Ideally, team

teaching utilizes the coordinated expertise of several faculty members to

achieve a common course goal.

At its

best, team teaching provides the students with a wide range of challenging

and eye-opening viewpoints on a broad subject matter expounded by different

faculty members who themselves are the experts and authorities in their area

of specialization.

Method

for selecting a team teaching partner

Some

teachers may believe that there is only one perfect partner teacher for them;

others feel that the philosophies of team teachers must be identical. Others

insist that team members should not be clones of each other, as differences can

contribute to creativity and growth of the individual team members. Robinson

and Schaible6 recommend that collaborative team teaching be limited

to two people, as good team teaching is too complex with more than two

teachers.

Roles

in groups of three or more teachers

Often

there is need for a team leader when the team is larger than two or three

members. The team leader is in charge of internal operations of the team, such

as setting up meetings and coordinating schedules. The team leader is also

responsible for external operations, for example communicating with department

heads to ensure that the team is meeting departmental goals or that the

resources and support are in place. The role of each team member is to

participate in team discussion and planning sessions. The members must act

responsibly and follow through on decisions made by the team within the

timeframe decided upon by the team.

Planning

Prior to

implementation, the team members should have sufficient professional

development in the area of team teaching; they should understand the philosophy

behind team teaching and the rationale of how it will fit with the rest of the

departmental program. Team-teaching partners need time to foster a trusting and

open relationship in which team-building discussions are encouraged, and as

well they need to be clear about their responsibilities and the time

requirements involved with their particular form of team teaching.

Following

implementation of a team-teaching program, educators must then continue to

"identify, implement and analyze the variables needed for every student to

succeed".7 Team members teaching the same class at the same

time should meet daily or weekly to make important decisions about

·

What will be

presented (e.g., the units, lesson objectives) and in what order,

·

How the material is

to be presented (e.g., to a large or small group presentation),

·

Who is to present the

information,

·

How the students

will be assessed, and

·

How small groups

will be organized and which team teacher will be assigned to each small group.

After

the team-teaching program has been in effect for a few weeks or months, the

team members should focus on improving their team teaching program by posing

questions such as

·

How can the class activities be improved,

·

What problems have arisen, and

·

How can these problems be solved

Generally,

the following fundamental rules are followed to achieve a successful team

teaching practice:6-8

EXPERIMENTAL METHODS

Various experimental methods (though not directly linked to the topics discussed in teaching methods of this paper) for learning about biomaterials are studied as additional tools to evaluate the failure behavior of biomaterials. Instructional lectures on each experimental method are given during each group’s (having a maximum of five students) laboratory classes. Each group has one laboratory class of three hours duration per week. A written laboratory report is required to be turned in by the students before the commencement of next experiment/laboratory class. The ultimate goal of these practical exercises is to provide hands-on experience for students in analyzing fracture behavior in biomaterials. Also, we strongly believe that these laboratory exercises help students in developing their learning, analyzing and creative thinking skills/abilities.

As already mentioned in the course methodology, mechanical testing, including micro-indentation hardness testing, fracture-toughness testing, ball-punch deformation test, and inclusion analysis are all carried out in the first half of the semester. Detailed studies on micromechanics of fracture in biomaterials are carried out in the second half of the semester.

Typically, ten micro-hardness measurements are made on the samples by each group of students. In the present case, testing was considered to be light force since the size of indentations (diagonal length) is less than 20 μm. Thus, hardness numbers obtained from indentations with diagonals measuring less than 20 μm are much more sensitive to variations of a few tenths of a micrometer in the actual or measured length of the diagonals than hardness numbers obtained by measuring larger indentations. Vitallium alloy, due to its very small size required mounting. Sufficient care is taken to ensure that the specimens are well supported in the mounting material. Also, the surface to be tested is placed into the test instrument such that it is normal to both the loading and optical axis. The optical quality of the microscope is such that highly corrected objectives with numerical apertures of 0.9 and greater are used. In addition, dark field illumination and differential interference contrast are used to improve the contrast of the image. This also helps to enhance the user’s ability to detect the ends of the indentations.

Microvickers hardness tests are carried out using a Shimadzu micro-hardness testing machine using a load of 100g. The procedure adopted for this test is as per the standard ASTM-E384. The Vickers hardness (HV) is calculated using the formula:

HV = 1854.4P/d2

Where the load P is in grams-force and the average diagonal d is in µm. The Vickers hardness value is constant over a very wide test load range for a homogeneous material due to geometrically similar indentations.

EXPERIMENTAL DETERMINATION OF FRACTURE TOUGHNESS

Two fracture toughness tests are performed by each student group. Plane strain fracture toughness (KIC) is a materials parameter of considerable engineering significance. The American Society for Testing Materials (ASTM) has developed detailed procedures for determining KIC. Frequently, a standard compact test (CT) specimen is used to experimentally determine the fracture toughness of materials. The critical value of K at fracture is calculated using the expression:

KIC = (Pf/BW1/2) f (a/w) where

Pf is the fracture load, B is the specimen thickness, W is the specimen width, and f(a/w) is a calibration function/correction factor. Variations of this procedure are recommended for polymers, ceramics and very thin metallic wires where the considerations for loads, rates and gripping are quite difficult. To obtain toughness values for very thin materials like the present orthodontic wires, a test very similar to the hardness test is frequently used.

BALL-PUNCH DEFORMATION TEST PROCEDURE TO EVALUATE FORMABILITY

Three ball-punch deformation tests are carried out by each group of students. The ball-punch deformation test is widely used to evaluate and compare the formability of metallic sheet materials. Biaxial stretching is the predominant mode of deformation occurring during the test. However, precise correlations between the cup height as determined by this test and the formability of a sheet material under production conditions have not been established.

An erichson cup testing machine equipped to hold about 10 kN

was used for this test. A minimum of three tests is carried out for each test.

The speed of the penetrator is 0.2 mm/s, but the speed is reduced to lower

the limit in order to more accurately determine the end point. The preferred

method for determining is by the drop-in load on the specimen. In general,

this indicates the onset of necking in the dome. Since the size of the test

specimen in the present case is very small, sufficient care is taken to determine

the end point. Comparison of ball-punch deformation test results shows compliance

with the specification of biomaterials regarding formability characteristics.

DETERMINING THE INCLUSION

CONTENT BY AUTOMATIC IMAGE ANALYSIS8 (ASTM E1245-2000)

Two measurements are performed

for assessing the inclusion content by a student group. The indigenous or

second-phase constituents in stainless steel are viewed with a light microscope

and scanning electron microscope using a suitably prepared metallographic

specimen. The image is detected using a television-type scanner tube (solid

state or tube camera) and displayed on a high-resolution video monitor. Inclusions

are detected and discriminated based on their gray-level intensity differences

compared to each other and the unetched matrix. Measurements are made based

on the nature of the discriminated picture-point elements in the image.9

These measurements are made on each field

of view selected. Statistical evaluation of the measurement data is based

on the field-to-field or feature-to-feature variability of the measurements.

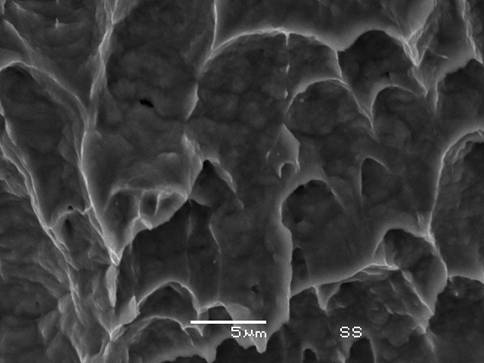

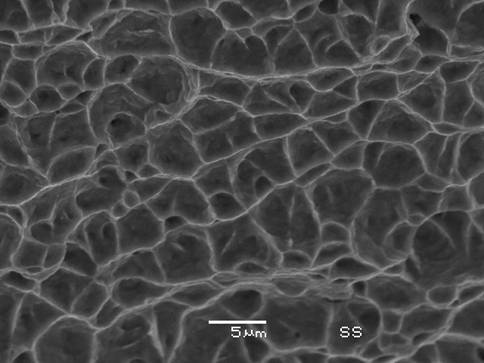

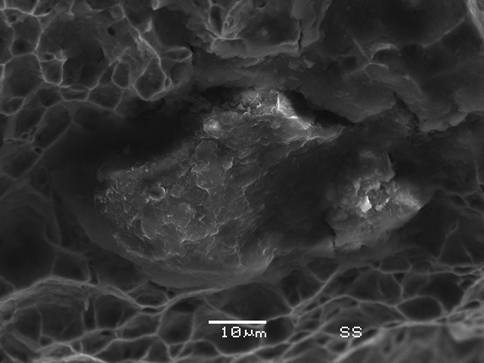

MICROMECHANICS OF FRACTURE

ON SS NAILS FOR SHINBONE AND VITALLIUM ALLOY

Every student is encouraged to actively participate during

this study on micromechanics of fracture. Fractured surfaces of biomaterials

are studied using SEM JEOL Model JSM 5910

Fig. 2 Presence of dimples characteristic

of ductile fracture at final fracture zone in Vitallium alloy

Fig. 3 Presence of a non-metallic inclusion in SS alloy

METHODS OF ASSESSMENT

The following methods are used to assess students’ performance

and the effectiveness of the course.

STUDENT PERFORMANCE

In lecture classes, three tests (one each month), two quizzes, one final, and a final project are given in a semester to assess the performance of students.

Typical laboratory quizzes, each about 15 minutes (containing

15 questions), is given at the end of each laboratory experiment/exercise.

These are usually multiple-choice type questions to evaluate students’ perception

of each experiment. Small-group discussions are also arranged to enhance the

level of learning of an experiment. At the end of the course, individual as

well as cumulative performances of students are evaluated based on quizzes.

EFFECTIVENESS OF THE COURSE

The course is evaluated during the

mid-semester period, as well as at the end of each semester. Numeric values

have been assigned to the various rating scales for the purpose of computing

medians. The scale values used are as follows:

Excellent = 5 Very Good = 4 Good = 3 Fair = 2 Poor = 1 The typical questions used for evaluating the course are· The objectives/learning outcomes for each part of the course were clear.

· The required tests, quizzes, and projects accurately measured my attainment of these learning outcomes.

· The course was well organized.

· The required reading and assignments contributed to my learning

· The class room discussions contributed to my learning.

· The instructor inspired interest in the course material.

· The instructor provided timely feedback.

· The instructor's feedback was clear and useful.

· The instructor treated students with respect.

· The instructor provided opportunities for students to learn from each other.

· The instructor was available and helpful

This evaluation method has been very useful in assessing and then improving the course content and methodologies.

CONCLUSIONS AND REMARKS

To summarize the learning outside technique, the

participating lecturers should be made to realize the importance of playing the

supporting role and to stay focused on the topic assignments in order to make

the entire production unified and outstanding. This kind of well-coordinated

teamwork will bring a rich and colorful educational experience that will

benefit both learners and teachers especially on specialty topics like

biomaterials.

No single

model of team-teaching will automatically result in success for a given

teaching situation. Any team-teaching program must be customized to suit the

curriculum, teachers and students. Team teaching can make learning a

cooperative and growing process for both students and the teachers. Team

teaching will be attractive to those who want to make learning a joint-life

experience between the team of teachers and their students.

Failure-analysis approaches, including micro-hardness/fracture

toughness, ball-punch deformation test for formability, and determination

of inclusion content using image analysis technique provide useful technical

information for evaluating merits and demerits of biomaterials.

REFERENCES

[1] Brettle, J., A Survey of the Literature on Metallic Surgical Implants, Injury, Vol. 2, No.26, 1970.

[2]

[3]

[4]

Smith, G.K., “Systemic Aspects of Metallic Implant Degradation,”

In Rubin L (ed): Biomaterials in Reconstructive Surgery,

[5] Williams, D.F., A Review of Metallurgical Failure Modes- In Orthopedic Implants, NBS Special Publication 472, 1977, p 11-16.

[6] Robinson, B., and R. Schnaible, “Collaborative teaching: Reaping the benefits”, College Teaching, 1995, Vol. 43, No.2, pp 57-60.

[7]

[8]

Maroney, S., Team Teaching, <http://www.wiu.edu/users/mfsam1/TeamTchg.html>,

[9]

Vander Voort, G.F., Metals Handbook: Materials

Characterization, ASM,

Biography of Dr. K.V. SUDHAKAR

Dr. K. V. Sudhakar is a Professor Titular in the Department

of Mechanical Engineering at Universidad de las Americas-Puebla in

Biography of Dr. TADEUZ MAJEWSKI

Dr. Tadeuz Majewski is working as a Professor Titular in the

Department of Mechanical Engineering at Universidad de las Americas-Puebla in